North American B-25C/D Mitchell

Airfix, 1/72 scale

S

u m m a r y : |

Description and Item No.: |

Airfix Kit No. A06015 - North American B-25C/D Mitchell |

Contents and Media: |

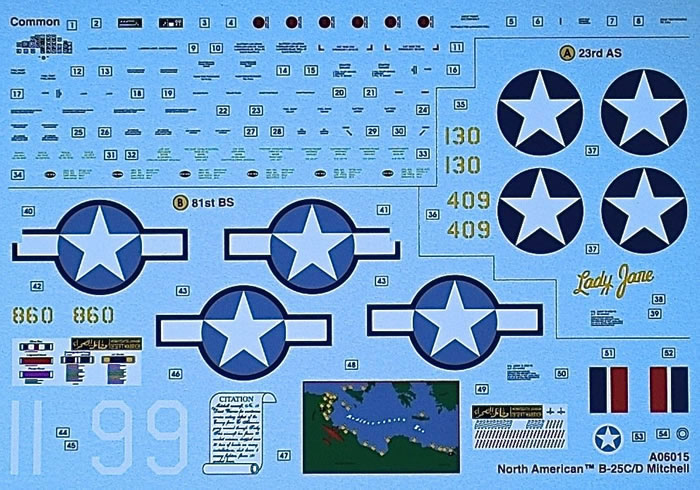

128 parts in light grey styrene, 24 clear parts, and one decal sheet with markings for 2 airframes. |

Price: |

£20.41 Plus Shipping at Hannants

$26.25 US Plus Shipping at Roll Models

$30.38 Plus Shipping at Hobby Link Japan |

Scale: |

1/72 |

Review Type: |

First Look |

Advantages: |

Crisp detail with scale appropriate inscribing and rivet lines; low parts count with simple engineering; quality decals covering two colorful schemes. |

Disadvantages: |

None noted. |

Recommendation: |

Beautifully molded parts with crisp, scale-appropriate rivets and panel lines, crystal clear canopy parts, low parts count, and straightforward engineering make this one of the best of the new breed of Airfix kits. |

Reviewed by John Miller

Airfix's 1/72 scale Tomahawk Mk. IIB is available online from Squadron.com

The North American B-25 Mitchell was an American twin-engine, medium bomber manufactured by North American Aviation (NAA).

The design was named in honor of Major General William "Billy" Mitchell, a pioneer of U.S. military aviation. Used by many Allied air forces, the B-25 served in every theater of World War II and after the war ended many remained in service, operating across four decades. Produced in numerous variants, nearly 10,000 Mitchells rolled from NAA factories. These included a few limited models, such as the United States Marine Corps' PBJ-1 patrol bomber and the United States Army Air Forces' F-10 reconnaissance aircraft and AT-24 trainers.

The Air Corps issued a circular (Number 38-385) in March 1938 describing the performance they required from the next bombers: a payload of 1,200 lb (540 kg) with a range of 1,200 mi (1,900 km) at more than 200 mph (320 km/h). Those performance specifications led NAA to submit their NA-40 design. The NA-40 had benefited from the North American XB-21 (NA-39) of 1936, which was the company's partly successful design for an earlier medium bomber that had been initially accepted and ordered, but then cancelled. However, the company's experience from the XB-21 contributed to the design and development of the NA-40. The single NA-40 built flew first at the end of January 1939 and went through several modifications to correct problems. These improvements included the fitting of 1,600 hp (1,193 kW) Wright R-2600 "Twin Cyclone" radial engines, in March 1939, which solved the lack of power.

In March 1939, North American delivered the substantially redesigned and improved NA-40 (as NA-40B) to the United States Army Air Corps for evaluation. It was in competition with other manufacturers' designs (Douglas 7B, Stearman X-100, and the Martin Model 167F) but failed to win orders. The aircraft was originally intended to be an attack bomber for export to the United Kingdom and France, both of which had a pressing requirement for such aircraft in the early stages of World War II. However, the French had already opted for a revised Douglas 7B. Unfortunately, the NA-40B was destroyed in a crash on 11 April 1939 while undergoing testing. Although the crash was not considered due to a fault with the aircraft design, the Army ordered the DB-7 as the A-20.

The Air Corps issued a specification for a medium bomber in March 1939 that entailed 2,400 lb (1,100 kg) load over 1,200 mi (1,900 km) at 300 mph (480 km/h). NAA used the NA-40B design to develop the NA-62, which competed for the contract. There was no YB-25 for prototype service tests. In September 1939, the Air Corps ordered the NA-62 into production as the B-25, along with the other new Air Corps medium bomber, the Martin B-26 Marauder. Both were order straight “off the drawing board.”

Early into B-25 production, North American made a significant design change to the wing dihedral. The first nine aircraft constant-dihedral wings, meaning the wing had a consistent, upward angle from the wing root to the wingtip. This design had stability problems that were remedied by "Flattening" the outer wing panels, giving them a slight anhedral outboard of the engine nacelles. This modification nullified the problem and gave the B-25 its gull wing configuration. Less noticeable are changes that included an increase in the size of the tail fins and a decrease their inward tilt.

After continued development during 1940 and 41, the B-25A entered USAAF service. The B-25B was operational in 1942. Combat requirements lead to further developments. Before the year was over, North American was producing the B-25C and -D series at different plants. Also in 1942, the company began design work on the cannon-armed B-25G series.

The gunship design concept dates to late 1942 and was started in response to a report from a North American field representative sent to the Pacific Theater. The NA-100 of 1943 and 1944 was an interim armament development built at the Kansas City complex known as the B-25D2. Similar armament upgrades by U.S-based commercial modification centers involved about half of the B-25G series. Further development led to the B-25H, B-25J, and B-25J2. The factory-produced B-25G entered production during the NA-96 order followed by the redesigned B-25H gunship. The B-25J reverted to the bomber role, but it, too, could be outfitted as a strafer.

North American Aircraft has the distinction of being the first company to produce trainers, bombers, and fighters simultaneously (AT-6/SNJ Texan, B-25 Mitchell, P-51 Mustang). It produced B-25s at both its main Inglewood plant and its plant at Fairfax Airport, Kansas City.

(Edited from Wikipedia)

Introduction

I’m old enough to a remember a time when one could count on hearing the rumble and roar of at least one B-25 at most airshows. The sight and sound of this aircraft in flight is something to be experienced.

Like many aircraft modelers of the “one true scale,” I’ve awaited the arrival of this kit with anticipation. The wait was worth it. This kit shows a fidelity and finesse in the inscribed details that make it one of the best of the new breed of Airfix kits and that says a lot: a sincere “Well Done” to the crew at Airfix.

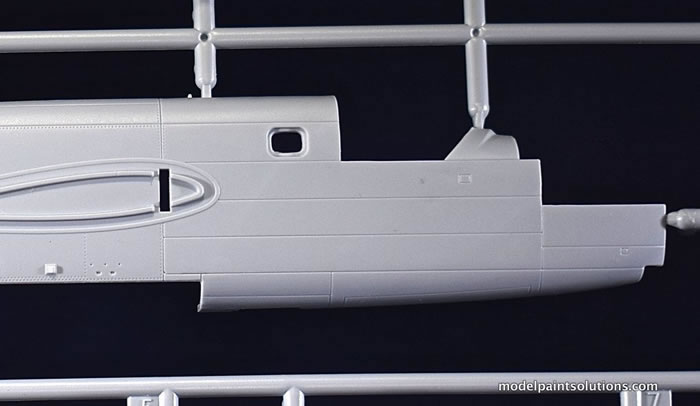

The 5 sprues of light-grey plastic carrying a total of 128 parts come in one large plastic bag along with two individually bagged sprues of clear parts (24).

In addition, the familiar Airfix-style instruction booklet, a small decal sheet, and two large (11.5 x 16.5 inch) foldout sheets each with 4-view, color images of the two schemes covered by the decal sheet are found in the bottom of the box. An additional large 6-view sheet showing airframe stencil data and placement are provided: very nice.

Initial impressions are exceedingly positive. The panel lines and recessed details, in particular, stand out as having been done with scale-appropriate restraint.

The recessed panel lines on the new Airfix kits have been getting progressively better (finer: less wide and deep). The inscribing on this B-25C represents a substantial improvement over their previous 1/72 offerings, which were pretty good in their own right. This is a step up.

On this point Airfix deserves to be acknowledged for listening to the criticisms of some of their earlier kits and responding with inscribing that exhibits increased fidelity and finesse.

Side by side (literally) with some of these beautifully inscribed lines are very nicely rendered lines of “rivets” represented by very small indented holes. I suspect that there will be some that don’t like this kind of inscribed detail but as with any detail method, it’s largely a matter of taste and preference. That said I like them.

The clear parts exhibit crystal clarity, flash-free molding, and easily pass the Model Paint Solutions “Antique Model Magazine Test.” Moreover the canopy framing is appropriately scaled and raised sufficiently for easy masking and painting. Of note are very slight line-like imperfections in some of the panels of the earlier A model canopy piece. These “lines” are slight and only visible when viewed at a specific angle. Perhaps they are just in my example? Whether they are a consequence being ejected from the mold or related to plastic flow during the molding process is unclear.

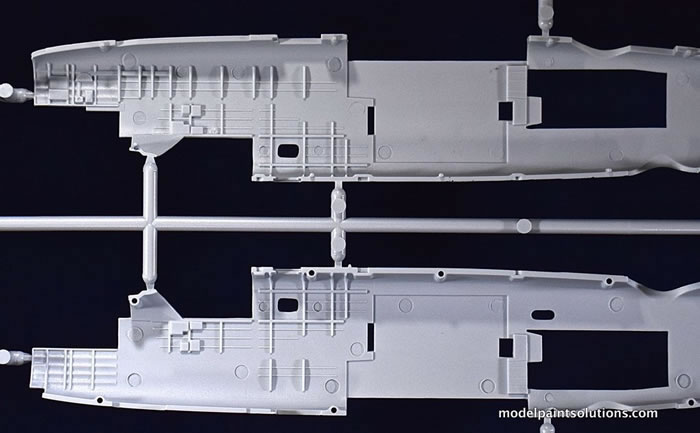

Construction starts, not surprisingly, with the multi-part cockpit, which is very nicely detailed although harnesses will have to come from the spares box. The cockpit assembly incorporates the bombardier’s station as well as the front wing spar. The details provided on the cockpit side panels are beautifully molded and will look great under some carefully applied paint and a wash.

Next in sequence the builder has to decide whether the bomb bay doors will be displayed opened or closed. Alternate parts are provided permitting either configuration. The opened option incorporates beautifully detailed bomb bay side panels, bomb racks, and four 500-pound bombs. A nice piece of engineering are the large clear panels that fit on each side of the fuselage just ahead of the dorsal turret. These panels have one small circular and one small oblong-shaped window in them and obviate the need to glue small and more difficult to handle windows pieces. With the clear panels in place, the cockpit and bomb bay (?) are trapped between the fuselage halves completing the assembly. On to the wings………

In a deviation from more conventional builds, the instructions suggest that the lower halves of each wing be glued to the spars and side of the fuselage first. After a “landing light” piece is installed into each lower halve, the upper halves are then glued in place: interesting.

The remainder of the build is quite conventional. Of note both the elevators and rudders are poseable. Similarly, the builder is given the option of assembling both the inboard and outboard flaps posed up or down. Moreover the elevators and flaps are nicely molded single pieces: very nice.

The three-piece engine assemblies are nicely detailed straight from the box. Likewise, the nicely molded landing gear and wheels will look great under paint and a little weathering.

Last in the building sequence are the clear parts including the upper and lower turrets. That the turrets can be left off until final assembly is a nice piece of engineering that will make masking and painting much easier.

This looks to be a straightforward and easy build with no issues apparent other than too many models and insufficient time.

Markings

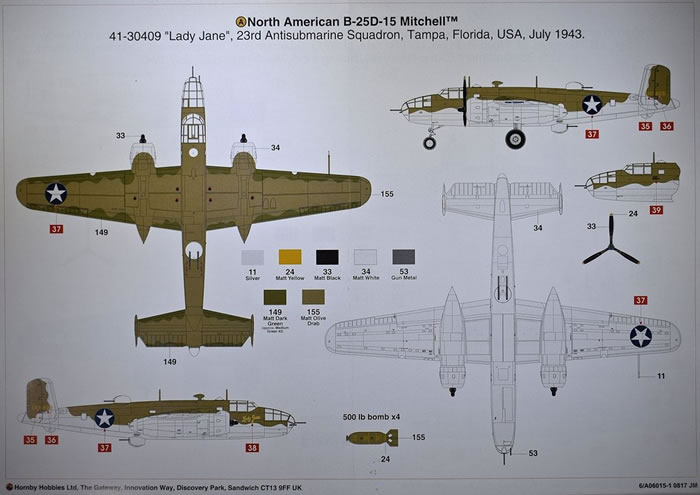

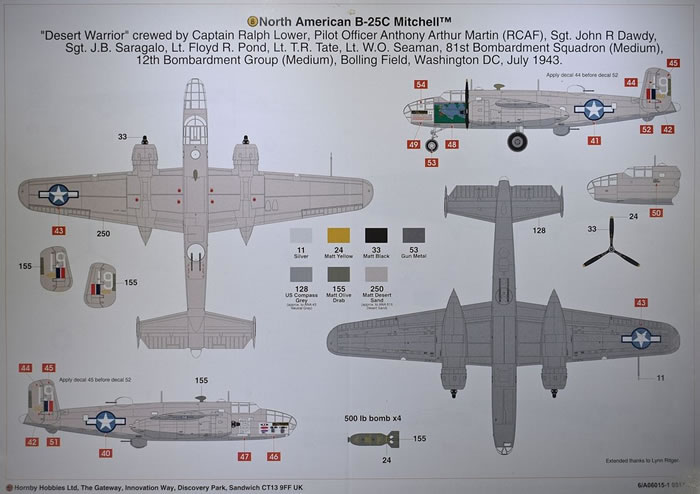

The decals, printed by Airfix, have excellent registration and appropriate color and hue. In addition to the colorful map-like decals used with option B, the airframe stencils are crisp and well printed. Markings are provided for two schemes:

A) North American B-25D-15 Mitchell, #41-30409 “Lady Jane”, 23rd Antisubmarine Squadron, Tampa, Florida, USA, July 1943.

Matt white belly and under surfaces with Olive Drab uppers accented with wavy Dark Green areas on the leading and trailing edges of the wings, the leading edges of the horizontal stabilizers, and trailing edges of the elevators.

B) North American B-25C Mitchell, “Desert Warrior” crewed by Captain Ralph Lower, Pilot Officer Anthony Arthur Martin (RCAF), Sgt. John R. Dawdy, Sgt. J. B. Saragalo, Lt. Floyd R. Pond, Lt. T. R. Tate, Lt. W. O. Seaman, 81st Bombardment Squadron (Medium), 12th Bombardment Group (Medium), Bolling Field, Washington DC, July 1943.

US Neutral Grey belly and under surfaces with Desert Sand (pink) uppers and mixed markings consisting of USAAF “stars and bars” on fuselage and wings and an RAF fin flash.

Aviation author, accomplished modeler, and the man behind A Scale Canadian.com, Jim Bates, graciously offered some additional information on this interesting scheme:

The eagle-eyed modeler may have noticed that the “Desert Warrior” markings option provided in the new Airfix B-25C/D Mitchell lists a crewmember, Anthony Arthur Martin, as Pilot Officer (RCAF). Why is there a RCAF crewmember in a USAAF Mitchell?

Following Churchill and FDR’s Second Washington Conference in 1942, the 12th Bomb Group was transferred from the U.S. to North Africa and attached to the newly formed 9th Air Force. The 12th BG was tasked with assisting the British Eighth Army in their battle with Rommel's Afrika Korps. As the unit was inexperienced, it was decided to transfer 23 RCAF wireless air gunners (WAG) to the unit to assist learning British radio procedures and to prevent friendly fire incidents. The Canadians served at two bases -Devesior in the 81st and 82nd Bombardment Squadron and Ismalia with the 83rd and 434th B.S. Four RCAF WAGs were killed during their year with the 12th BG, and two, Alan James Mackie and Anthony Arthur Martin were awarded the U.S. Distinguished Flying Cross. F/O Anthony Arthur Martin, from Squamish, British Columbia, was also awarded the American Air Medal and Six Oak Leaf Clusters for his service with the Earthquakers.

It is assumed that when “Desert Warrior” returned to the United States for a bond tour, F/O Martin was selected to accompany the tour due to being the highest awarded RCAF WAG in the group.

This is a beautifully molded kit with restrained, scale-appropriate inscribing and crisply executed rivet lines and surface details. With a low parts count and very straightforward engineering, this should be a quick and easy build that will provide sufficient detail straight from the box. When the nicely printed decal sheet with markings for two particularly colorful schemes is added to the mix I suspect this will be a popular kit indeed.

For more on this review visit Modelpaintsolutions.com.

Kit purchased by the reviewer

Review Text and Images Copyright © 2018 by John Miller

Page Created 11 April, 2018

Last updated

11 April, 2018

Back to HyperScale Main Page

Back to Reviews Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search