|

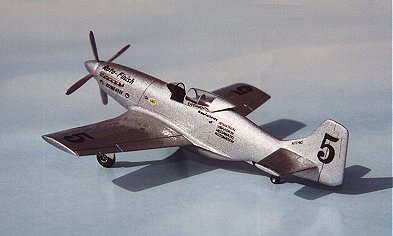

P-51

"Roto Finish" Racer

by

Alex Bernardo

|

|

Roto-Finish Racer |

Kit:

Academy 1/144 P-51D Mustang

I

picked this airplane because it was an "Eye Catcher"! I also

thought that a single color aircraft would make an easy transition into

civil aircraft category. I

picked this airplane because it was an "Eye Catcher"! I also

thought that a single color aircraft would make an easy transition into

civil aircraft category.

Boy, was I wrong! There was nothing easy about this project. |

-

There

was no cockpit to speak of, so off I go to constructing an entire cockpit

made of various sizes of styrene, which included: Main instrument panel,

side control console, various gauge panels on both sides of the cockpit,

Cockpit floor, new seat w/ seat and headrest cushions, and seatbelts, Rear

fuel tank, radio boxes, control stick made out of wire, and main instrument

panel shroud. There

was no cockpit to speak of, so off I go to constructing an entire cockpit

made of various sizes of styrene, which included: Main instrument panel,

side control console, various gauge panels on both sides of the cockpit,

Cockpit floor, new seat w/ seat and headrest cushions, and seatbelts, Rear

fuel tank, radio boxes, control stick made out of wire, and main instrument

panel shroud.

-

External modifications included cutting back

main wing tips and horizontal stabs. Shortened main intake scoop. Lengthened

the trailing edge of the wing root towards the tail of the aircraft. Added

exhaust door panels on the bottom. The spine from the vertical stab and

canopy was raised to accommodate new canopy profile. To achieve the new

spine profile, I glued a narrow section of 1/72 scale drop tank on to the

spine. The seams were filled with super glue and sanded to a smooth finish.

-

Since this is an air racer it should have an

unblemished look. With that in mind, the majority of the recessed panel

lines were filled in w/ small strips of styrene and super glue, and then

sanded down and then polished to a smooth finish. Panel lines around the

engine and wing root were retained to show some definition.

-

Adding a styrene disk on to the base of the hub

lengthened the propeller hub. The propeller blades were repositioned

according to new length of the hub.

-

The existing canopy was modified into the new

low profile racing canopy configuration as a male mold for creating

"Heat-n-Smash" canopies.

-

I printed the markings on to decal paper using

a laser printer at work. Any colors were painted on before coating the

decals w/ liquid decal film.

I

figured the painting phase was the home stretch. NOT! I applied the silver

paint. Then I put on the initial clear coat. Next, the decals were put on.

Homemade decals with a lot of coverage like these numbers tend to be

thick. With that in mind, several cycles of applying a clear coat and wet

sanding was repeated to create a smooth finish over the decals. What a BIG

PAIN IN THE BUTTOCKS! I

figured the painting phase was the home stretch. NOT! I applied the silver

paint. Then I put on the initial clear coat. Next, the decals were put on.

Homemade decals with a lot of coverage like these numbers tend to be

thick. With that in mind, several cycles of applying a clear coat and wet

sanding was repeated to create a smooth finish over the decals. What a BIG

PAIN IN THE BUTTOCKS!

I followed the directions from the polishing kit to achieve the final

results. It's a good thing this a small model, otherwise it might be

sitting on my workbench at home, instead of here. |

Models, Description and Images Copyright ©

2000 by

Alex Bernardo

Page Created 16 May, 2000

Last Updated 26 July, 2007

Back to HyperScale Main Page

Back to Features Index

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search