|

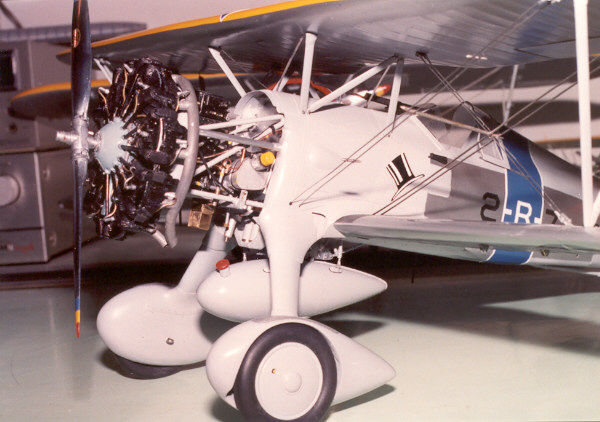

Curtiss BFC-2 Goshawk

by

Arlo Schroeder

|

|

|

Scratchbuilt 1/16th

Scale Curtiss BFC-2 Goshawk |

Text

by Ben Backes

HyperScale is proudly sponsored by Squadron

This model represents the 3rd section

lead of VB-2B “High Hat Squadron” aboard the USS Saratoga circa 1936.

Building time for this project was 1,391 hours.

Features include working shock absorbers on the

landing gear, working control surfaces and hinged engine access panels.

Automotive acrylic lacquers were used to paint this

model, and markings were custom-made dry transfers from Woody Vondracek.

Construction

Photo Feature

|

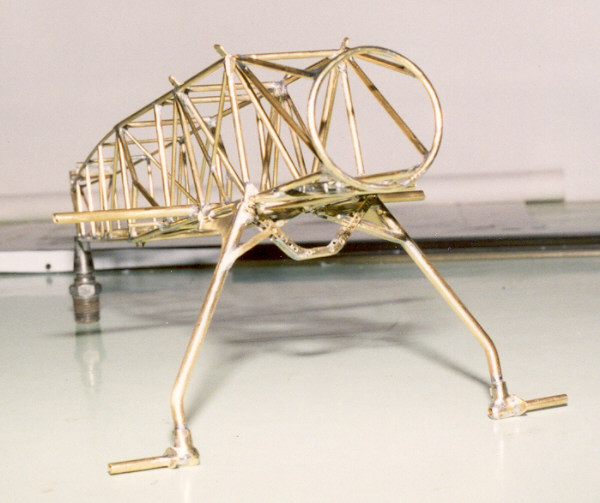

- The internal structure and landing gear is

soldered brass tubing.

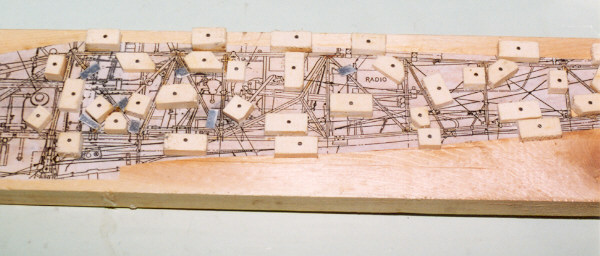

- This was accomplished with the aid of a

soldering jig. First a drawing of the internal structure was glued to

a piece of wood, then small wooden blocks were nailed at strategic

locations with the proper angles cut into the corners to hold each

piece of tubing in its proper location while the soldering was done.

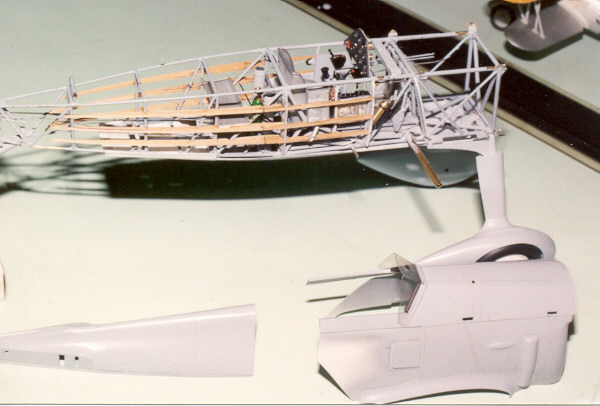

- Arlo used real wood stringers to simulate the

real wood stringers!

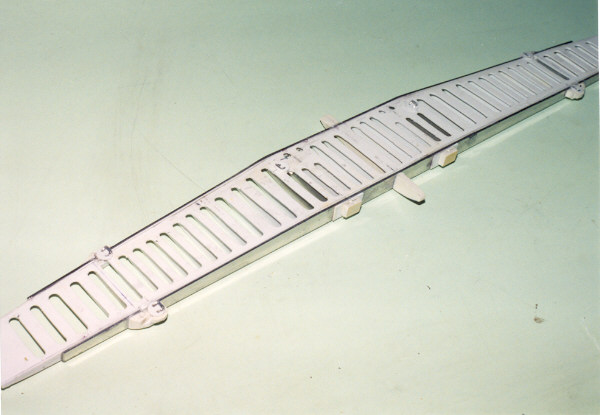

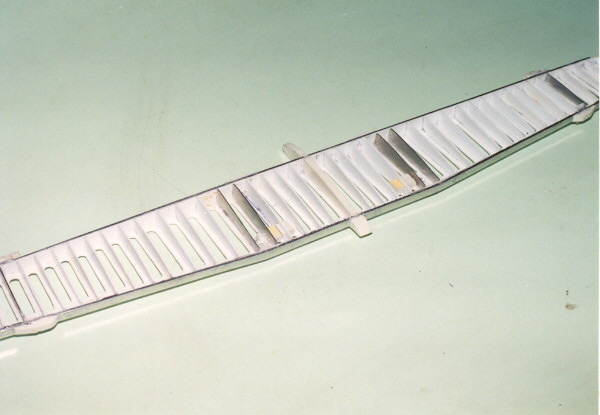

- Underside of the upper wings internal

structure. Sheet aluminum sandwiched to the plastic spars adds

incredible strength. The attachments for the struts are metal too.

- Upper view of the upper wing internal

structure. Plastic was used for most of the spars, but were the

struts attach aluminum was used for added strength.

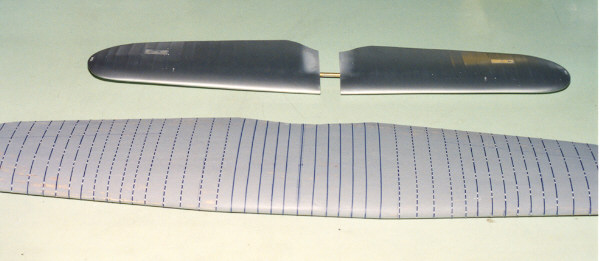

- The finished lower wing sits behind the wood

pattern for the upper wing skin. Thin pieces of tape were laid along

the location for each rib. When the skin is vacuum-formed these will

create raised bulges. It looks as if small sections of blue tape are

in some places, but this is not actually the case. Different colors

of scrap tape were used and some of the pieces were alternating blue

and white patterns.

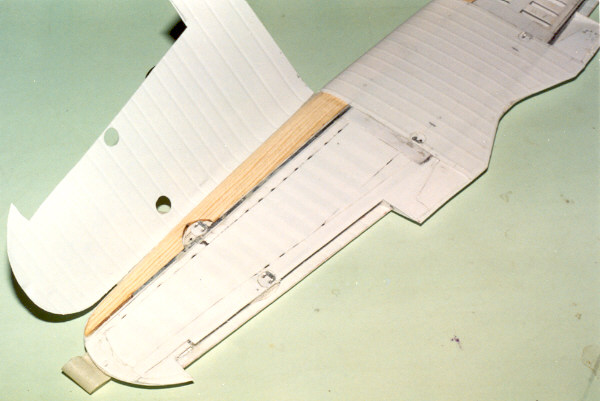

- This is the underside of the upper wing, before

the skin is applied. Wood has been carved and glued to the aluminum

to provide something solid behind the skin of the leading edge.

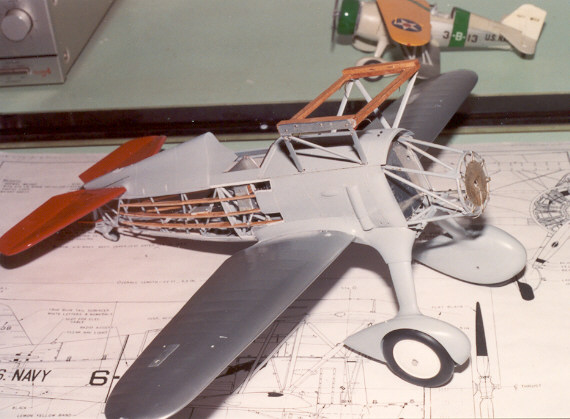

- Many of the major components painted and ready

for final assembly.

- The wood box is a temporary jig to get the upper

struts lined up correctly.

- The Wright R-1820 engine is attached and behind

it is the accessory section. The flying wires are flattened aircraft

model safety wire.

Model and Images Copyright ©

2001 by Arlo Schroeder

Text Copyright ©

2001 by Ben Backes

Page Created 10 October, 2001

Last Updated 04 June, 2007

Back to HyperScale

Main Page

Back to Features Index

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search