|

Reggiane Re.2001

by Brett

Green

|

|

|

Reggiane Re.2001 |

Classic

Airframes' 1/48 scale Re.2001 is available online at

Squadron

During 1940, the airframe of the

lacklustre and unreliable Reggiane Re.2000 was adapted to the Daimler-Benz

DB 601. The resulting design was more streamlined than the original

radial-engine Re.2000, and the German in-line powerplant improved

performance dramatically. This new combination was officially designated

the Reggiane Re.2001.

Following numerous design

changes and production difficulties, the Reggiane Re.2001 entered service

in September 1941. The Re.2001 proved that it was a match for its main

adversary, the Spitfire Mk. V, over the skies of Malta and on bomber

escort missions during 1942. The Re.2001 continued to see active service

with diminishing effectiveness until the armistice in September 1943; and

limited action beyond this date with the Italian Co-Belligerent Air Force.

|

Classic Airframes’ Re.2001 In The Box |

Classic Airframes 1/48 scale

Re.2001 is packed in their familiar black-trimmed box adorned with

attractive art by Don Greer. The parts count is surprisingly small – 32

styrene pieces on two sprues, 18 crisply cast resin parts, 9 clear parts

(only 3 are used), a vacform canopy and a spare.

The first impression upon

opening the box is the high quality of the plastic mouldings.

The plastic is finished in a

shade of “Tamiya Grey” and features very crisp, very fine surface detail.

Panel lines, vents and grilles are all convincingly rendered, and fabric

surfaces are subtly realistic. There are no sink marks or other

imperfections on the outside of the plastic, but the larger parts suffer

from prominently raised ejector pin “buttons” that will need to be removed

before assembly.

Click the thumbnails below to view larger images:

The plastic is quite shiny and

resembles the material currently favoured by the mainstream manufacturers,

although Classic Airframes’ plastic is a little softer.

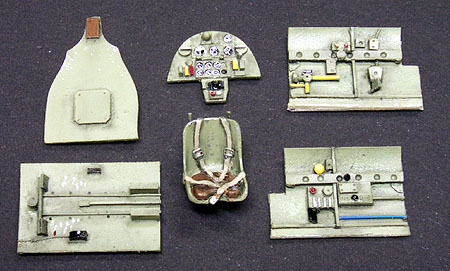

Resin

parts are supplied for the cockpit, the exhausts, intake, radiators and

small scoops. These are also very well done. The cockpit is adequately

busy although more detail might be added if desired. The seat features a

cast-on cushion, a harness plus rear rails.

This

multi-media model is rounded out by the inclusion of three tiny sprues of

coloured navigation lights. One sprue is translucent green, one is

translucent red and one is clear.

Any

model requires careful preparation. Classic Airframes’ Re.2001 is no

exception.

The

high-quality mouldings do not alter the cottage-industry origins of the

kit design. From previous experience, I knew that extra care would be

required with the fit of the cockpit, the wing to fuselage join and

alignment, and with the cleanup and/or fabrication of minor details.

Wings

I

commenced with the wings. The trailing edges of the wings looked quite

thin, but I decided to sand them a little thinner. Classic Airframes

supply round resin wheel-well inserts. These feature prominent casting

plugs on top of the wheel well. Fortunately, the resin is quite soft and

easy to sand. I used a coarse, damp sanding stick to reduce the waste, but

the rear of the well still fouled against the top wing even after a large

pile of resin muck had accumulated. I sanded the back of the resin circles

at an angle until I could almost see daylight through the roof of the

wheel well. This was sufficient to clear the top wing. I glued the top

wing halves to the full-span lower wing.

Click the thumbnails below to view larger images:

|

|

|

|

Resin wheel inserts in place after sanding

|

|

|

|

The mess resulting from sanding one wheel well insert!

|

|

|

The

interior of the two radiator housings were painted, and the resin

radiators received a coat of silver and a generous wash of thinned black

oil paint. The radiators were too tall for their housings so I took the

easy route and sanded the resin to fit. These were super-glued into their

housings and added to the lower wing.

Cockpit

The

resin cockpit components look good in their sealed plastic bag, but they

look even better after a coat of paint and an oil wash. The

resin cockpit components look good in their sealed plastic bag, but they

look even better after a coat of paint and an oil wash.

I tried

to match the suggested cockpit interior colour, FS 34558, with a mix of

Gunze H312 and Tamiya XF-57 Buff. The resulting colour actually looks like

a pale shade of RAF Interior Grey Green. After a wash of thinned black oil

paint, I picked out details with Tamiya acrylics. I did suffer from a case

of brain fade and painted the instrument panel Interior Green when the

instructions (and reference photos) clearly call for the panel to be

black.

The kit

instructions imply that the cockpit should be assembled prior to

installation in the fuselage. One word of advice – DON’T!

If the

cockpit is assembled as logic would suggest, with the cockpit floor

trapped between the sidewalls, the whole assembly will be several

millimetres too wide to fit in the fuselage. I also found that the

sidewalls as supplied would be located a few millimetres too far forward,

hiding the instrument panel way behind the coaming.

I

followed this sequence:

1.

The waste on the rear bulkhead was sanded until it was very thin.

2.

The fuselage halves were taped together.

3.

The armoured rear bulkhead was dry-fitted. Note that the top of

this part rests in front of the rear fuselage upper deck. In the

absence of locating pins on the fuselage interior, this dry-fitted

bulkhead acts as a point of reference for the other cockpit components.

4.

The fuselage sidewalls were removed from their casting blocks. I

also scored along the bottom horizontal line on each of the sidewalls

and removed the material below this line.

5.

I dry-fitted the fuselage sidewalls. Note that the right-angled

cutout in the front of the sidewalls is where the instrument panel will

be located. It looked to me that the panel would be located too far

forward so I made a vertical cut at the rear of the sidewalls to remove

around two millimetres of resin.

6.

With the rear bulkhead still dry-fitted, I glued the shortened

sidewalls to the fuselage interior using super-glue.

7.

The instrument panel was dry-fitted inside the taped fuselage. I

found I could easily manipulate the panel with a pair of tweezers. The

panel only needed a light sanding around the upper contours to achieve a

perfect fit.

8.

The seat and control column were glued to the cockpit floor. I

mounted my seat well forward on the small moulded blocks. Even so, the

seat barely cleared the rear bulkhead.

9.

The cockpit floor was inserted in the taped fuselage halves for

test-fitting. The floor should sit in front of the rear bulkhead; and

align with the bottom of the resin sidewalls.

10.

The tape was removed and dry-fitted cockpit components stowed for

later assembly.

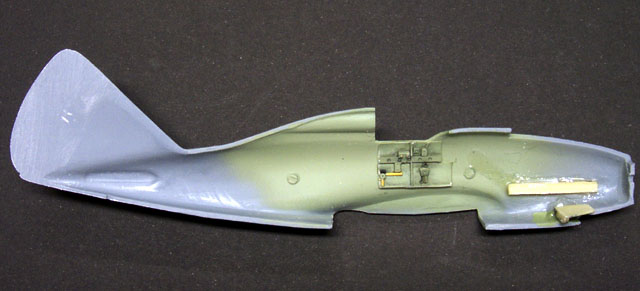

Fuselage

The

fuselage needed a little more preparation before assembly. The inlet for

the oil cooler was partly flashed-over, so I cut it open with a sharp

hobby knife. The oil cooler bath is supplied in resin. I painted the part

and glued it to one fuselage half.

The

exhaust stacks are also resin parts. The locating slots in the fuselage

sides were too short and fractionally too narrow. I used a knife to

lengthen the slots and a sanding stick to correct the height. The resin

parts were a tight, gap-free fit. I flowed super-glue around the back of

the exhausts to ensure a permanent bond.

I ran a

sanding stick around the joining surfaces of the fuselage halves with

special attention to the trailing edges of the rudder.

The

fuselage halves were now taped together. Care is required for perfect

alignment – there are no locating pins on this kit. When I was happy with

the alignment of the fuselage halves, I applied Tamiya’s Super Thin Liquid

Cement to the joins with the tiny brush provided.

When the

fuselage had set, I removed the tape and slid the resin rear bulkhead into

place behind the sidewalls. I ran a bead of super glue down each side of

the back of the bulkhead through the bottom fuselage opening. Next came

the instrument panel. Using tweezers, I carefully manoeuvred the panel

into place on top of the notches in the fuselage sidewalls. Once again a

bead of super glue was applied to the back of the panel to secure it

permanently. A few spots of super glue were applied to the bottom edge of

each sidewall and the cockpit floor was also secured in place.

I did

not add the resin gunsight at this stage, as I was concerned that it would

interfere with the alignment of the panel or be knocked off during later

handing.

The

forward upper cowl is supplied as an insert. This part features nice deep

gun troughs, but no holes for the gun muzzles. I drilled holes behind the

troughs using a twist drill, and inserted fine brass tube to represent the

muzzles of the 7.7 mm guns. At first, the cowl part seemed too wide for

the fuselage, but after some minor trimming and juggling it actually

fitted very well.

Sub-Assemblies and Details

The

horizontal tail surfaces are a simple butt-fit against the fuselage side.

I wanted to reinforce this join so I drilled holes in the fuselage

tailplane roots and the mating surfaces of the tailplanes. A short spar of

brass rod with a few dabs of superglue was inserted. I secured the bond

further by flowing Tamiya Super Thin Liquid Glue into the join lines.

The wing

and fuselage assemblies were test-fitted. I noted a step between rear of

the lower wing and the fuselage. I trimmed the wing root and the problem

disappeared. Dry-fitting suggested that the upper wing root join would be

very good, but that there would be a slight gap at the front and rear of

the bottom of the wing.

I glued

the wing to the fuselage. The wing root join was almost perfect, but the

lower wing needed filling and smoothing with a little Tamiya Putty and Mr

Surfacer. I rescribed the panel lines on the lower rear fuselage at this

point.

I also

added a few lines of Mr Surfacer to seams on the upper fuselage.

Click the thumbnails below to view larger images:

|

|

|

|

Excellent fit between upper wing and fuselage at wing root |

|

|

|

Slight gaps on lower fuselage at front and rear wing joins

|

|

|

|

Gaps filled with Tamiya Putty, sanded and panel lines restored

|

|

|

The spinner was glued to the

backplate with the addition of a short length of Contrail plastic tube

behind the hole in the spinner boss. This tube was necessary to blank off

the hole from broad daylight.

Minor

details such as the scoops, bomb rack and navigation lights were now

secured. I also added a pitot tube. Some photos show a strange bulbous

shape towards the end of the Re.2001’s pitot tube. I used a filament from

a big industrial light bulb to represent this peculiar shape.

The

undercarriage legs are oversimplified as supplied. I therefore detailed

the gear legs with lead foil and fusewire. The three gear covers for each

side were thinned down before securing them to the gear legs using

superglue. The

undercarriage legs are oversimplified as supplied. I therefore detailed

the gear legs with lead foil and fusewire. The three gear covers for each

side were thinned down before securing them to the gear legs using

superglue.

I

drilled a shallow hole in the upper wing using a 2mm twist drill. The

location of this hole is indicated by an indentation on the inside surface

of the upper wing. The new hole was deep enough to accept the locating pin

of the gear legs. The completed undercarriage legs were secured with a

combination of liquid cement and super glue.

Drag

struts are not supplied so I cut four length of 1mm diameter Contrail

plastic rod for the job. The picture above shows the struts located too

low down the gear legs. I corrected the position of the struts at a later

stage.

The kit

wheels looked okay, but I decided to use the True Details resin wheels for

Macchi C.202/205 (Stock No. 48031). I bought these wheels in 1995 – I knew

they would come in handy sometime!

Diversity of colour schemes is not the strong suit of the Reggiane

Re.2001. On the other hand, if you appreciate green and grey, you will

love this aircraft!

I

decided to add a dash of colour by finishing my bird as the aircraft on

the cover of the Squadron book,

“Reggiane Fighters In Action”. This Re.2001 has a yellow nose and

spinner.

The

vacform canopy was packed with Blu-Tak and masked with tiny strips of

Tamiya masking tape. The Blu-Tak preserves the shape of the canopy while

it is being masked, and also eases the task of slicing the part away from

its backing sheet. The masked canopy was shot with a coat of interior

green followed by my equivalent of Verde Olivia Scuro.

Force of

habit led me to pre-shade the panel lines in black despite the dark upper

surface colour. I also sprayed the wingwalk area black, then masked the

walkways before proceeding. Next, the fuselage band and cross of the

“House of Savoy” were roughly sprayed onto the fuselage and rudder. I also

sprayed the nose and spinner using Tamiya XF-3 Flat Yellow with a tiny

spot of red. When dry, these markings were carefully masked off. I also

masked the tips of the navigation lights using Blu-Tak.

Gunze

Acrylics were used for the main camouflage colours. I used H308 Gray FS

36375 for the lower surfaces, and H420 RLM 80 Olive Green for the uppers.

Click the thumbnails below to view larger images:

|

|

|

|

Black pre-shading plus white and yellow markings ready for masking...

|

|

|

|

Basic camouflage colours applied. A coat of Testors Metalizer Sealer has been applied. Ready for decals...

|

|

|

|

Decals and black oil wash completed. Waiting for weathering...

|

|

|

|

Almost finished! Walkway chipping and exhaust stains are complete. A coat of Gunze Flat Clear has been applied.

|

|

|

When the

camouflage paint was dry, I prepared the model for the decals.

In his

recent article on

building

Classic Airframes’ Re.2001 on Modeling Madness, Lynn Ritger suggests

the use of Testors Metalizer Sealer as a prep coat for decals. I tried

this on my own Re.2001 and was delighted with the results. Metalizer

Sealer provides a hard, smooth finish and dries in minutes.

Decals

were a combination of kit markings (national markings, the fasces,

stencils and the chick kicking up dust on the rudder) and decals from Sky Models

“Caccia Reggiane” sheet (Squadriglia and individual aircraft

numbers). The kit decals are especially worthy of mention for their

thinness, opacity and cooperative nature. The Sky Decals were also a

pleasure to work with, but the red individual aircraft number “6” was a

somewhat translucent.

|

Weathering and Final Assembly |

I

applied a thin black oil wash to the upper surfaces of the model. The

Metalizer Sealer took the wash very well.

Some

wear and tear was added either side of the wing walkways using tiny spots

of Tamiya Chrome Silver applied with a 10/0 brush. The exhaust stain

comprised a sooty brown-black mix with a blob of Tamiya Flat base,

followed by a thin streak of chalky grey over the top.

This

stain was also heavily applied to the lower mid-fuselage behind the

engine.

A coat

of Gunze Flat Clear was sprayed over the entire airframe and the final

components were added:

·

The gunsight

was glued in place and an acetate lens added

·

The vacform

windscreen was secured with White Glue (which also acted as filler)

·

The folding

canopy was sliced in two and rejoined at the hinge line using 1mm plastic

rod. This new assembly was then glued to the cockpit opening

·

The tailwheel

and mainwheels were glued into place

·

A spot of

Future was applied to the tips of the navigation lights, furnishing an

appropriate lustre that was missing earlier

·

The tail

navigation light was glued in place

·

Smoke-coloured

nylon mending thread was used for aerial rigging

I

thoroughly enjoyed building Classic Airframes’ Reggiane Re.2001.

The new

metal moulds result in a quality of plastic that, until recently, could

only be expected from a mainstream Japanese manufacturer. The surface

detail and texture of the styrene really is first-rate.

However,

quality of plastic alone does not define a “mainstream” kit.

In

common with Classic Airframes’ earlier releases, this kit does not have

locating pins and the modeller needs to fabricate some minor details to

complete the kit. Be prepared to expend a little extra effort in

preparation and test fitting too – especially for the cockpit and

wing-to-fuselage join. This preparation will be rewarded with a highly

detailed and attractive model.

Classic

Airframes’ 1/48 scale Re.2001 is an ideal candidate for the modeller who

wants to test out his skills on something slightly more challenging than a

Tamiya single-engine fighter kit.

Click the thumbnail to view

the larger image on this page.

Thanks to Jules Bringuier of Classic Airframes for the

sample kit.

Text, Images and Model Copyright © 2001 by

Brett Green

Page Created 01 October, 2001

Last Updated

04 June, 2007

Back to HyperScale Main Page

Back to Features Index |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search