Squadron.com

It has not been easy to model an A-4M Skyhawk without "moving

mountains" in scratch building and detail work. I did it once using Monogram

A-4E/F and OA-4M kits. I was happy with the result, and I always wanted to do

another. But, being unwilling to tackle the conversion a second time with

Monogram kits, I just let it go.

Times have changed. Along came Hasegawa with a simply gorgeous A-4E/F kit. All

the desire to build another A-4M came out in force. All I needed was some time

to start grafting Monogram OA-4M pieces onto it -- NOT! I knew that surely

someone would release a conversion to make my life easier. Either that or

Hasegawa would release an A-4M kit of its own. Just before IPMS Nationals in

July of 2002, the former of these possibilities happened with Cutting Edge

releasing an A-4M conversion for the Hasegawa A-4E/F kit. Of course, this was

not a huge surprise, since I did help with some of the research. For a review of

the Cutting Edge A-4M conversion, click here.

Then, I needed decals to put on this A-4M model. All the major manufactures have

released Skyhawk decals to go with the Hasegawa (and HobbyCraft) Skyhawk kits.

But Cutting Edge was first with a series of sheets dedicated to the A-4M (in

support of their conversion set). For a review of the Cutting Edge A-4M decals,

click here.

I originally started this model before the IPMS Nationals with the intent to

finish in time to take it to Nationals so Cutting Edge would have a finished

model to point at with all their new A-4M releases. With model building being a

motivational exercise (for me), I needed to maintain motivation to finish this

project. Sadly, after pushing hard on a number of time-critical projects

completions early in the year, my motivation levels in July were starting to

drop. When I hit a minor snag, the model missed getting done for National. In

fact, it only finally got done this month. I have to apologize to Cutting Edge

for not getting the model done in time.

I am not going to get into the basic Hasegawa kit here. I have

written several reviews of the various versions already released by Hasegawa.

You can go to these reviews to read all the great things about these kits. The

point of this writing is to discuss the Cutting Edge A-4M conversion to the

Hasegawa A-4E/F kit.

Cutting Edge A-4M Conversion

To build an accurate middle or late production A-4M requires

some changes to the cockpit, especially the main instrument panel and instrument

hood. Not wanting to do this on this model (and knowing the Cutting Edge was

already planning to release a late production A-4M cockpit set), I chose to

build an early production A-4M. The first A-4Ms (early production) were quite

similar to the A-4F in their avionics fit and thus their cockpit

instrumentation.

The conversion of the A-4E/F kit into an early production A-4M really only

requires one fuselage cut. The cut is made on both fuselage halves in the area

of the cockpit. Cutting Edge provides insert pieces that replace these areas of

the fuselage so as to correct the shape of the cockpit canopy and windscreen.

This change, by itself, is the only heavy surgery needed to turn an A-4F into an

early A-4M. The pictures below show the cuts to the fuselage halves and the

fitting of the insert pieces.

|

|

|

| Cockpit

Fuselage Cuts

|

Fitted

Cockpit Side Walls

|

The only other surgery required is the installation of the APU

exhaust port on the right fuselage. Cutting Edge provides the exhaust port. All

that is needed is to create an appropriately sized hole in the correct location

on the right fuselage. Sounds easy, huh? Well, it was. I eyeballed the location

of the APU exhaust from reference pictures and drilled a pilot hole with a small

diameter drill bit (0.037"). I then enlarged this pilot hole with a 1/8" drill

bit (which matches the size of the Cutting Edge APU exhaust piece.

Note that the APU exhaust comes out parallel to the ground, not perpendicular to

the lower engine intake contour. After drilling the hole in the fuselage, I

twirled the drill bit in the hole as I pulled up on the angle of the drill bit.

This re-contoured the hole to place the exhaust port at the correct angle.

Cutting Edge created the exhaust port with a uniformly squared off pipe. The

Cutting Edge instructions say to glue in the APU exhaust, then trim off the

excess. I prefer getting the shape right before gluing, so I filed down one side

to change the lip of the pipe to match the contour of the fuselage side. Then, I

glued it in place. See the following pictures to better show what I am trying to

describe.

|

|

|

|

APU Exhaust Port Location

|

Filed

Down Exhaust Pipe

|

|

|

|

|

Drilling Angle for the APU Exhaust Port |

Completed APU Exhaust Installation |

With what I thought was the last of the surgery behind me, I

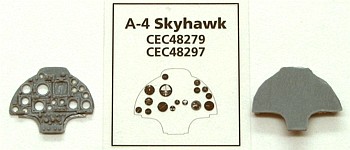

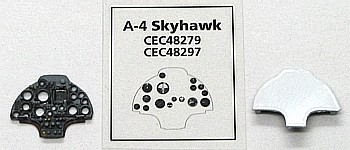

continued to build the kit. I chose to use the Cutting Edge A-4 Skyhawk cockpit

set (CEC48279). This is an A-4F cockpit, but it is correct for an early

production A-4M. I even decided to give the main instrument panel the sandwiched

acetate treatment as provided in the Cutting Edge set. See the pictures here for

the outcome of my work.

|

|

|

Unpainted Main Instrument

Panel |

Completed Main Instrument Panel

|

|

|

|

Painted Main Instrument Panel |

Completed Cockpit Tub |

The only trick to watch on the cockpit assembly is the alignment of the back

wall. If you look at the fuselage around the cockpit, you will see a diagonal

panel line running down from the rear quarter point of the cockpit sill. This

panel line corresponds to the location of the back wall of the cockpit. When

attaching the back wall into the cockpit tub, I needed to check and recheck the

alignment of the wall with this panel line. After three attempts at it, I

finally got it to align where I wanted it. Once aligned correctly, the rear deck

piece fits perfectly into the thinned out lip area of the fuselage at the rear

of the cockpit.

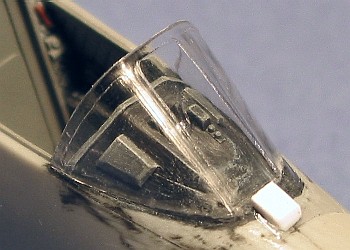

After assembling the fuselage, I went to install the instrument hood over the

main instrument panel and forward cockpit. Since Cutting Edge provides no piece

for this in the basic A-4M conversion, I turned to the kit piece. For an early

production A-4M, the kit piece details are correct (with only a gunsight, no HUD),

but the piece is quite a bit too small for the enlarged opening of the cockpit.

I added strip styrene around the kit piece to enlarge it so it could fill the

needed space. I used 0.020" styrene strips, 0.100" wide on either side of the

kit piece. Then added some small scraps to the forward area to finish the work.

It was crude, but it was enough to mount the piece onto the fuselage. Gobs of

super glue did the rest for fairing the enlarged instrument hood into the

fuselage, under the windscreen.

It was this issue (modifying the instrument hood) that ultimately deep-sixed

getting the project done for Nationals. In my opinion, it would not have been

hard for Cutting Edge to provide a replacement instrument hood in the basic set.

If you want to build an early A-4M (that does not use the late cockpit update

set), use my measurements above and pictures below to guide your work on growing

the kit instrument hood to fit the enlarged A-4M cockpit opening.

|

|

|

|

Modified Hood -- Top

|

Modified Hood -- Bottom

|

Modified Hood -- Installed

|

With the instrument hood attached, I painted the area and then attached the

windscreen. The fit was less than perfect, but nothing that I could not fix. The

upper nose is a rounded surface. The leading edge of the windscreen is straight.

After consulting some pictures of A-4M windscreens, I found the top of the A-4M

nose is a bit flattened to work with the revised windscreen, so I used a flat

file and flattened the top of the nose a bit to better match the windscreen. A

little super glue along the edges completed the filling of the seams.

One detail item missing in the conversion is the rain removal and de-icing vent

in front of the windscreen. I added this detail using a short piece of 0.030"

strip styrene. The image below (left) shows the attached windscreen with the

rain removal and de-icing vent.

|

|

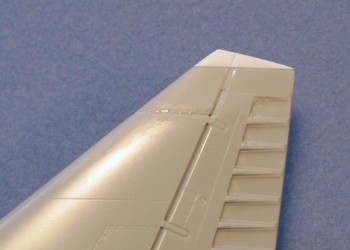

Another revision to the kit involved the top of the vertical

tail. As an early production A-4M, this model has the squared fin tip (kit part

A14). I have never liked the squared fin tip as molded by Hasegawa. The Hasegawa

part has a "level" contour that just does not look right to me. After some

research and study of pictures, I finally determined what bothered me about it.

The tail top I was seeing in pictures of real A-4Ms was not "level". It slopes

upward a bit to create a point at the leading edge of the tail tip. I attached a

small strip of styrene to reshape the tail tip and used super glue to blend it

in. The other image (above right) shows the modified tail tip. Right or wrong, I

found this shape looked better to me.

Shortly after I made this tail tip modification, the new Ginter book on the A-4M

was released. Pictures in that book further proved my opinion that the tail top

sloped upwards. They also showed that a pronounced notch was formed between the

moving rudder and the non-moving vertical tail. After comparing back and forth

with the pictures, I came to the conclusion that the rudder was not changed from

the shape it has on a rounded top tail. It appears that a new tail top cap was

added which provides the squared appearance, without changing the shape of the

top of the moving rudder.

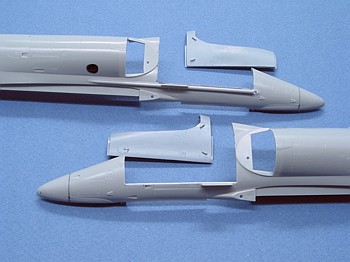

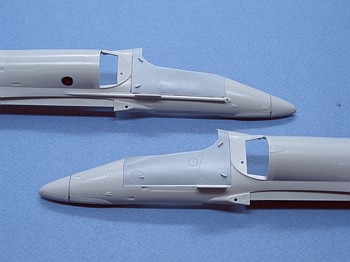

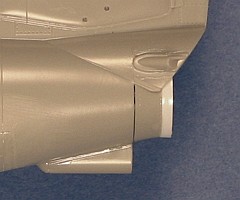

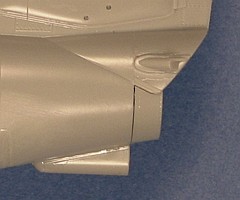

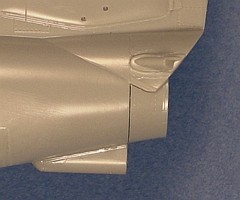

The next items to get attention were the engine intakes. Cutting Edge provides

the needed bulged intakes in the A-4F "Super Fox" conversion, which is a

required compliment to the A-4M conversion set. These intakes pieces are simple

replacements of Hasegawa kit pieces. After removing these pieces from their

casting blocks, I test fitted them on the model. I was dismayed to find them a

bit too small. A substantial step appeared in the outline of the fuselage where

the rear of the intake piece meets the fuselage.

After some study, I found the easiest way to fix the issue was to add a spacer

to the rear of the intake pieces. I pulled out some sheet styrene and laminated

a 0.015" thick piece of sheet styrene onto the intake piece. This eliminated the

step in the fuselage outline. The nominal increase in the thickness of the

intake splitter plate is not that noticeable. I informed Cutting Edge of this

problem, and they are verifying that their masters are good. They told me this

sort of thing is a sign that the molds are getting old and that they will fix

this for future production of the parts. The pictures below show the engine

intake with the spacer in place.

|

|

|

|

Modified Intake - Front

|

Modified Intake - Inner Side

|

Modified Intake - Top

|

The outer walls on the Cutting Edge engine intakes are a bit thinner than the

Hasegawa pieces that they replace. This made the gap inside the intakes more

noticeable than it was with earlier builds of the kit I had done. Adding the

0.015" spacers further increased this gap, making it so I could not ignore the

gap. I carefully wrapped some 0.005" styrene sheet inside the intakes to fill

the gap. This was not perfect fix, but it makes the gap less noticeable when you

look back the intakes.

Another item I revised was the engine exhaust. Originally, when Hasegawa

released their Skyhawk kit, I investigated it and saw the two engine exhaust

pieces. I thought the short one was for the majority of Skyhawk versions and

longer one was the lengthened version used on the "Super Fox" A-4F and A-4M/N.

Now that I am actually building a kit that I know needs the longer exhaust, I

took a closer look at the kit pieces and at pictures of the real aircraft. I

have come to the conclusion that the exhaust on the "Super Fox" A-4F and A-4M/N

is not actually longer than the basic Skyhawk engine exhaust, but is marginally

wider at its opening. Consider the following pictures.

|

|

|

A-4E Exhaust

|

A-4M Exhaust

|

Note how both exhausts are the same basic length. Also note how the contour of

the areas is different at the lips. While the A-4E exhaust maintains a

uninterrupted contour all the way to the exhaust lip, the A-4M exhaust has a

flair in the lip to provide a slightly wider opening. It is amazing how long you

can look at something and not actually see what you are looking at. I rechecked

the Hasegawa instructions for the various Skyhawk kits and found they tell you

to use the shorter and longer engine exhausts on various versions. It really

helps when I read the kit instructions, not just browse them.

From what I can tell at this point, the shorter engine exhaust (as provided in

the Hasegawa kit) is for the A-4A, A-4B, and early A-4C. The longer engine

exhaust (as provided in the Hasegawa kit) superceded the short one at some point

on A-4C aircraft and continued on with all subsequent aircraft until the A-4M.

The "Super Fox" A-4F and A-4M/N have a third style engine exhaust that is not

provided in the basic Hasegawa kit. This new style is not hard to make, though.

I created one for my A-4M model by starting with the shorter kit exhaust and

attaching some strip styrene to the lip that extended it. I used 0.015" by

0.060" Evergreen strip styrene. I carefully rolled the strip to the approximate

circle size and attached it to the shorter kit exhaust with liquid cement. When

I cut it to length, it was a bit short, so I had to cut a small piece of strip

to fill a gap left at the point where the two strip ends were supposed to have

met. The following pictures highlight the change I made to the kit piece.

|

|

|

|

Longer Kit Exhaust

|

Shorter Kit Exhaust

|

Modified Exhaust |

If you do not want to go to the trouble that I have gone to here on the engine

exhausts of your A-4M models, just use the longer kit engine exhaust piece,

unmodified. The difference in the final model is not really all that noticeable.

It is the kind of difference that only the person who built the model will see

in the final piece.

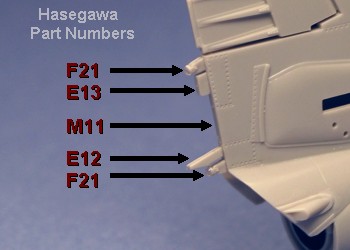

While I am on the subject of the tail area, the antennae configuration on the

trailing edge of the vertical tail changed with the A-4M as compared to the

A-4E/F. All the necessary parts are in the Hasegawa kit, I only needed to

consult some references to figure out which pieces to use a what locations. Note

that on early A-4M aircraft (and many A-4E/F), the spike antennae (kit parts

D19, E31, F21, and F22) are only fairings without the spikes. Close examination

of some pictures showed that there is a small rounded plug that covers the

mounting points of the spikes. I hacked off the spike antennae on the kit parts

and added small globs of super glue to represent the rounded plugs.

The image below (left) shows the correct early production A-4M configuration.

Note that this configuration was changed again for middle and late production

A-4M aircraft. Note also that while I point to where the formation light goes

(part M11), the actual clear part is not yet in place on the model.

|

|

|

Vertical Tail Antennae

|

400 Gallon Fuel Tanks

|

The other image (above right) shows my work to create 400 gallon wing fuel

tanks. The tanks provided by Hasegawa are the 300 gallon size. While these are

correct for use on any Skyhawk version, the A-4M tended to more frequently use

the larger 400 gallon type. This provided a bit more fuel, and the higher

powered J57-P-408 engine could deal with the added drag.

The 400 gallon tanks were constructed using the tail fin assemblies from the

Hasegawa kit (the lighter gray plastic), mated onto the Monogram A-4 Skyhawk

wing tanks (the darker gray plastic). While I have no actual dimensions for the

size of a 400 gallon tank, the observed size difference between the Hasegawa and

Monogram tanks seems about right for what I have seen in pictures. I chose to

use the Hasegawa fin assembly because I liked its shape and details better than

the Monogram provided fins.

The rest of the conversion amounts to using alternate pieces already present in

the Hasegawa kit.

I used the small Hasegawa kit provided ECM antennae on either side of the engine

exhaust (parts D17 and D18). Early production A-4M aircraft did not get the

larger bulbous antennae provided in the Cutting Edge set (although they did

eventually get retrofitted).

I added the parachute brake housing under the rear fuselage

(parts D11 and D28). Note that the kit provides two different parachute brake

housings. The part numbers I list here are correct for the A-4M. The other parts

pertain to other Skyhawk versions.

A-4M Skyhawks do not typically have the flare/chaff dispenser on

the left side of the rear fuselage. They only seem to have the dispensers that

are on either side of the arresting hook. So, I used the rear lower fuselage kit

part with no dispenser molded into it (part A6).

|

|

|

Right Side Static Ports

|

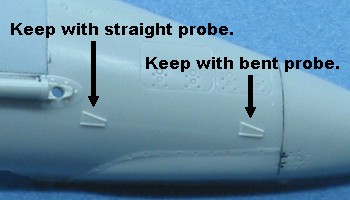

All A-4M Skyhawks use the bent refueling probe, so I attached

this (part E7) to the right side of the nose.

One thing not mentioned in the kit instructions pertains to the two static

points molded to the right side of the nose (small triangular shapes with raised

edging), just below and in front of where the refueling probe attaches. These

two items are mutually exclusive. You need to carve or sand off one of these

based on the type of refueling probe the aircraft has. Keep the rear static port

for aircraft with a straight refueling probe. Keep the forward static port for

aircraft with a bent refueling probe. Since I was using the bent refueling

probe, I kept the forward one and removed the rear one.

I constructed all the other antennae and details (not mentioned

here) to match what the Hasegawa kit refers to as "Scheme 2" (which is the

A-4F).

I chose to keep the weapons configuration minimal. I only built

up and attached the two wing fuel tanks. This was a fairly common loading for

the early years of A-4M usage.

Cutting Edge provided lots of choices for markings on this model. Limiting

myself to an early production A-4M limited my choices down to only two of

Cutting Edge's options -- VMAT-102 and VMA-214. I have never been a big fan of

the "Black Sheep", and I really like the colorful VMAT-102 markings, so I chose

to go with the VMAT-102 aircraft.

Great kit -- great conversion! Some care must be taken to get

the fuselage cuts in the right places. With care, the conversion parts fit right

into the prescribed places. With the recent release of the Cutting Edge A-4M

cockpit update, it looks like I will be doing another A-4M in a late

production configuration in the coming months.

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search