|

Tamiya's 1/48 scale

F4U-1A Corsair

by

Hubert Ortinger

|

|

|

Chance-Vought F4U-1A Corsair |

Tamiya's 1/48 scale F4U-1A Corsair is available online from

Squadron

Zinc-Chromate

Everyone who is interested in airplane model construction has surely

already certainly encountered the designation of zinc chromate. In order

to understand what ZCh. means in connection with the interior color of

US airplanes one must first know what ZCh is, and what it was used for.

ZCh is a resistant coating against corrosion, which was and/or still

becomes attached via different paint applications. Its highly toxic

composition protects the (metal) surface against damage and corrosion by

organic materials and provides a subsequent galvanizing.

Developed by the automobile industry, it was used from 1933 in aircraft

construction. At that time ZCh does not have a meaning as a color to

separate, rather as an undercoat and protectant. In crystalline form ZCh

has a bright greenish-yellow clay/tone and this color is emphasized if

it is mixed with a carrier. This mixture offers the basis for a

translucent painting, which was laid on usually in only one thin coat.

As a consequence, the coated surface has an influence on the finished

appearance. That means: on white/bright undergrounds ZCh appears rather

yellowish, on metals and dark surfaces rather greenish. Color additives

were also applied to change the resulting finish. In the direct prewar

time and initial phase of the war the pure base mix was usually used. To

make a more opaque and a more durable protection for fast wearing parts

and surfaces, it soon became common to add black lacquer whereby the

color became green. But there is sufficient proof that airplanes

exhibited different painting in different parts. For example light

yellow wheel housings, apple-green weapon bays and green cockpit. At

Vought even a pale-pink clay/tone existed, developed by the additive of

red color labeled “Salmon” was used as a method to indicate the second

coat.

While ZCh, technically seen, represented an effective corrosion

protection, the untinted finish was impractical for crew areas. The

garish interior painting coupled with the underlying metal dazzled the

eyes. This led to the use of different tinted green tones in cockpits

and other crew areas. In the year 1943 the name cockpit-green emerged in

the ANA (Army/Navy/Aircraft) agreement for the first time, whereupon the

Navy standardized the zinc chromates/black–mixture and starting from

1943 the designation ANA611 Interior Green. From then on it was the

colour used in all crew areas. After the war this color became official

for complete interior painting.

Nevertheless, it was quite normal for the lower surface colour and/or

light-grey to be used for the wheel housings and even the interior of

the engine compartment / cowling.

My Project

After I already outdone myself with my Wildcat with folded wings and

superdetail set, I intended to do the same with this Corsair, so I

wanted to detail the cannon bays and folded wings. However, since every

renowned modeler has already built “common” F4U, I wanted mine to be

somewhat special and unusual.

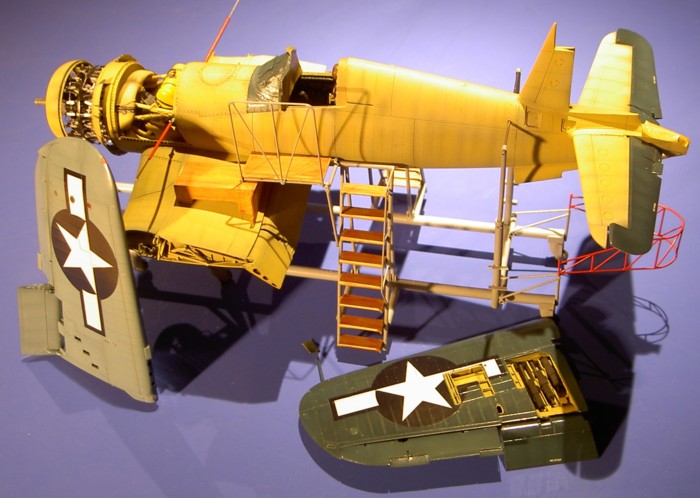

My decision was to depict an incomplete airframe on the assembly line

based on a photograph in the Squadron publication „Corsair in Action “.

But how I should build the factory assembly jigs?

The Assembly Jig

First I made various sketches on 1:48 copied side tears and searched

on innumerable photos for the exact „Jack here “position for jacking up

on the lower surface. After many unsuccessful attempts I finally had the

brilliant idea and it succeeded me to make the rollers out of plastic

sheets different strengths, and that six times, because I did not have

notion from pouring off.

Enormous amounts of plastic profiles were blended until finally I

“welded” the frameworks including the beams with “superadhesive“. A

model of the same type built in former times had to help me finding and

plumbing the correct gauges.

I strengthened the basis framework with a metal tube because the weight

of the airplane and the emphasis of the finished model had not to be

underestimated for safety's sake. Also the gauges of the platform

placeing on the wings had to be designed and estimations were determined

and then carved and glued from Sheet.

I soldered the hand rails of the steps, the railings of the bridgework

and the safety loop for the tail from curved brass wire. A unobtrusive

wood structure of the appropriate parts was depicted by pulling over

sandpaper.

I sprayed everything in semi gloss grey from Revell whereby I lightened

the longer pipes centrically and all welding seams became a whashing.

Descrete lacquer damage at some corners and edges were up-painted in

dark grey to give a used look.

The safety loop was painted red. For the wood grain I looked myself to

the WW I modelers, who use this technology with their flying cases. The

parts for it were primed with the colours sand and skin. After

sufficient drying time I took brown Oils and painted with an old brush a

rough wood structure on it which I wiped off after a few minutes with a

rag dampened with lighter fluid again.

Sounds easy - is also easy!

As the result turned out too little in the comparison to the airplane

high-contrast I later repeated the whole procedure with Vandikbraun once

again.

The Corsair

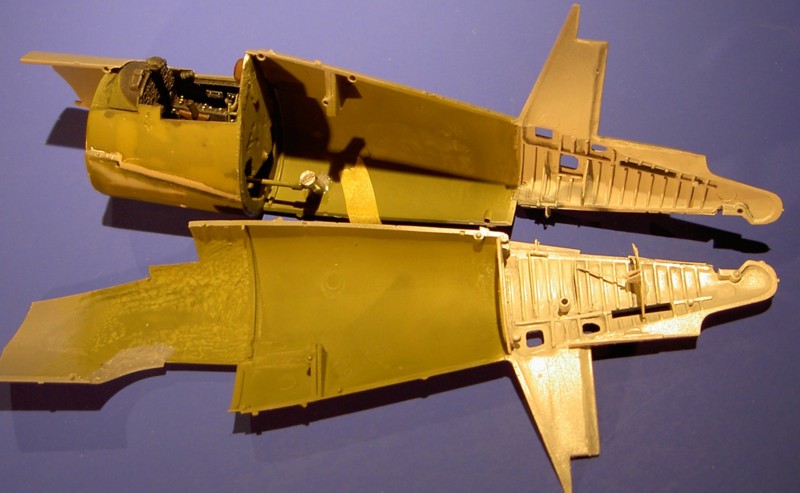

I began to install with the wing areas, the most important section

for me, because I wanted the wings not only folded but standing

perpendicularly to view both onto the folding mechanism and onto the

weapon bays. The Tamiya hinge arrangement for this option was incorrect

for it however both the Resin wheel wells and Resin weapon pits had to

be inserted in the way stood to a large extent uselessly there. The

intersection had to become completely grind and the mechanism had to

construct as well as the hinges from Evergreen material. As I did not

know to lend sufficient stability to the whole construction at this time

yet I considered, but for me was clearly that I would have to strut it

like the original.

The special fittings of Aires fit perfectly after the necessary place

for it was milled out and the appropriate portions (flaps) were sawn

out. For setting in the MG´s easily and becomming a more beautiful

transition of the openings at the wing leading edge I used suitable

plastic pipes. The ailerons and also all other control surfaces were

naturally sawn out and exchanged against their-same by Aires.

Additionally still all trim tabs were also modified. After I inserted a

fodder and the hinge mockups to conceal the view into the inside the

wings could be stucked. The position lamps at the wing ends were sawn

out and replaced with transparent plastics. The clunky pins on the

landing flaps which are attached separately in the kit were filed off

and I fastened them only to the joints and small bits wire. However

that´s sees not completely so stable for it but failed more filigree and

more original-faithfully.

The holes at the wing had to be closed then with plastics. By the

catapult heels I was not inspired - I cut them off and made it scratch.

At all everywhere something was filed and replaced and probably there

wasn´t many parts which were not changed and detailed in any way!

With the cockpit for example (a real gem), I wanted to be able to look

better inside so the seat had to developed. The seat basic stand is

stupid-proves cast on and must designed for my requirements and adapted

to the rear former.

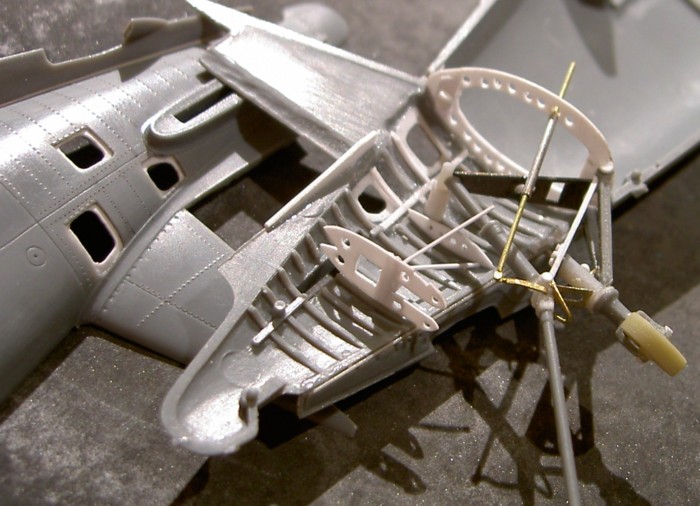

The engine is a kit for itself but nevertheless required still much

proactive. I added the ignition cables with thin fishing line and

detailed the ring which lead them to the cylinders and keep them away

from their heat at the same time. Painting the unit took place on the

foot and turned out rather difficulty because the exhaust manifold

unions was glued already there. Still to mark is that I had not to lose

it at no time from the eyes that I finally wanted to represent an

airplane fresh from the factory which the thing made still more

complicated.

It means low key weathering!

Until I was allowed to stick the trunk halves passed still much time I

also wanted the servicing covers for the tail landing gear opened there

and therefore copied the complete drawing in mechanism for this. I

prepared the construction in such a way that I had only to insert it

after painting. I did not replaced the acceptable tail landing gear

doors, but however detailed a model-fair closing mechanism.

In the pictures one can recognize the claimant expenditure better

than I can seizing it into words.

Occasionally I also employed with the main landing gear that required

exactly the same much attention by myself. Tamiya plans a loaded

chassis, but however my airplane hangs in air why I had the chassis leg

to show extend. In addition I first cut off the feather/spring shears,

replaced the absorber pistons by a metal pin, and stuck her far opened.

Also the mechanics on the front, which turns the wheel when drawing in

by 90 degrees is missing at the kit chassis and should be added. The

wheels seemed to me too thickly, why I divided, filed them thinner and

again stucked them together. There was no profile thereafter so I

decided somewhat to try out which I had frequently seen:

I painted the wheels anthracite coal, masked a groove profile and dry

painted with becoming bright grey at all. An amazing effect adjusted

itself!

At the separate rims I sanded so much away until the plastics between

the spokes discharged. Although the plastic parts of the kit for the

drawing in mechanism of the main landing gear are not bad but did not

fit with the model-fair linking in the Aires resin landing gear well.

Away with it! The reconstruction looks still more filigree. Over

stability I did not had to think!

Rosie the Riveter

Recently I bought “Rosie the Riveter” and finally decided to try it

out. Before I joined the fuselage halves I studied the airplane surface

and marked with a pencil, guided by model photographs, a little logic

and something imagination the structure of the rivet rows on the model

surface. I practiced handling the new instrument on cast-off parts until

I was finally ready. I applied the handle with light pressure following

the lines. The very much time-consuming occupation requires

concentration, above all at milled places the plastics was very thin or

with splices, which burst with too much pressure gladly again. For

several hours I did nothing else as to holes my model.

I did not think I was able to manage “stressed skin” on sheet metal ,

which was to be hurt however the original surface was anyway rather

smooth to owing the new spot welding procedure.

After sanding with finest Flies I was allowed to finally stick together

the trunk and with lower part. On the inside I still detailed the flap

for the compressor cooling before inserting the fire wall with the oil

tank.

At this frame now also the attachment for the struts to support the

outer wings in folded condition, which brought me on the idea to fasten

these in such a way that they could take over a basic function for the

wings itself. I drilled holes diagonally to the rear into the

substantial resinpart of the bulkhead , set in 0.5 mm steel wires which

were bent on the back and prevented to turn in the drillings with epoxy

adhesive. The bar was bent into the correct angle, and detailed in

accordance with the kit part and/or the original. The folded wing is not

only supported by this construction afterwards but is carried proper by

the bar!

Next I took care of the transparent cockpit glazing on which I always

put special attention. In addition I first paint the window brace free

hand in the colour of the cockpit interior and fix the windshield with

plastic adhesive at the trunk back. Then I mask the appropriate ranges

with small rigid Tamiya tape and embody the construction unit with

second adhesive whereby also wrong engravings can be filled.

After sanding these panel lines were engrved correctly. With the sliding

canopy I still detailed the levers for locking and three rear view

mirrors which were disguised with chromed metal foil inside. Not enough

with it at the entrance I engraved still the grooves in those the canopy

pushed back and forth.

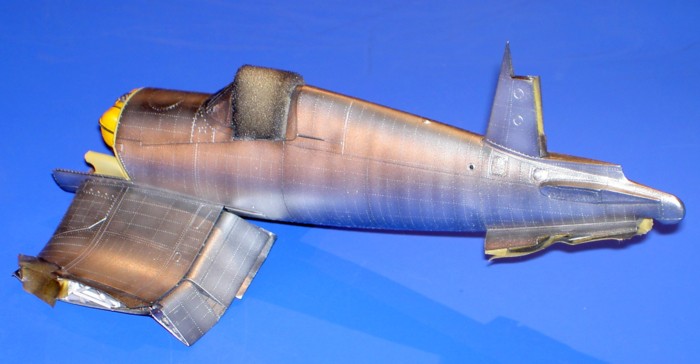

Before I made myself to fit in the engine as unit with its aggregates in

the fuselage front section, I fist had to paint the fuselage.

The evaluation of the available reverence material resulted in my

judgement that this range including all construction units as well as

the fuselage was to be painted in non-toned Zinck chromate. Since I

wanted to do only a thin glaze like on the original I first primed the

entire surface covering in shining black that followed by a thin layer

Alclad „white aluminum”. I sprayed up the Metal colour and the following

zinc chromate extremely time-consuming panel for panel, so that the

result could be affected . Finally the panel lines should be

recognizable without a washing. Since I really laid now chromate-yellow

on different coloured surfaces painted by me before , it was adjusted at

the beginning mentioned effect: Numerous different yellow tones were the

result!

The installation of the engine once again demanded my whole attention,

thereby the exhaust pipes had to fit to holes on the lower surface, cut

out for it. The cowling, against the Aires guidance had to be fastened

to the cylinders, so still before painting sixteen crescent-shaped

mounting plates was punched out and glued to the inside. Outside

appropriate rivets for it had to perforate.

As on the original photo recognizable, the outside wing areas, the

control surfaces of the height and vertical stabilizer and canopy which

were already pre-coated, and so I tried to reconstruct this proceeding

also at the model. I went without the metal priming, but did the yellow

protective coat. I sprayed all fabric surfaces grey. I mention here once

again that I so pedantically proceeded, because I had to represent an

exterior fresh from the factory and wanted to do without a washing!

For preshading on the top side of the wings I used the non-coloured and

pure colour, afterwards I easily lightened the panels. For the

structures of the rudders and fabric segments I lightened this clay/tone

again and afterwards then preshaded with it the engravings on the lower

surface and the horizontal tail. Also this intermediate blue was still

lightened twice. With the lower surface, stub wings and the center

section I began with light-grey semi gloss and brightened with shining

white to reach more depth also here. As a result of toning high gloss

„gloss sea blue” with semi gloss white arose a not too reflecting

finish, and also the semi gloss „Intermedia blue” offered still a

sufficiently smooth surface to apply the Decals perfectly, which I cut

out anyway sharply around. Since after a polish with „Micromesh” the

gloss level was almost identical I could save sealing.

Final Assembly

This involved bonding the control surfaces into angled positions,

fitting the landing gear parts including drawing in mechanisms and

draping the brake hoses from black painted cord. After inserting the

cannons and gluing the weapon pit- and ammunition-flaps to the outside,

the wing areas could be aligned finally perpendicularly standing and

were fixed after detailing the bolting device mechanics. I not simply

set on it but fastened the canopy in front and in the back with tiny

taps in the guide rails.

The engine compartment was still wired up with differently coloured

wires and where it appeared necessary and probable to me I still stuck

various maintenance plaques up.

After jacking up I provided one propeller blade with the label sketched

with “Window Word”: “Don´t rotate…”

Click the thumbnails below

to view larger images:

[../../photogallery/photo00004299/real.htm]

Model, Images and Text Copyright © 2007

by Hubert Ortinger

Page Created 04 October, 2007

Last Updated

24 December, 2007

Back to

HyperScale Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |