|

Model Design Construction's 1/32 scale

Hawker Typhoon Mk.Ib

by

Ian Robertson

|

|

|

Hawker Typhoon Mk.Ib |

HyperScale is proudly supported by

Squadron.com

The

Hawker Typhoon was intended as a replacement for the Hurricane in the

interceptor role for the British. When it was introduced in 1941 it

was the only Allied fighter capable of speeds higher than the Fw.190 at

low altitudes. However, the Typhoon was plagued by early design flaws

and never reached its full potential as a fighter for so long that it

was no longer needed in that role. The

Hawker Typhoon was intended as a replacement for the Hurricane in the

interceptor role for the British. When it was introduced in 1941 it

was the only Allied fighter capable of speeds higher than the Fw.190 at

low altitudes. However, the Typhoon was plagued by early design flaws

and never reached its full potential as a fighter for so long that it

was no longer needed in that role.

Following several design upgrades, the Typhoon’s

real forte as a hard-hitting ground attack aircraft was eventually

recognized and used to advantage by the Allies. Fitted with either

rockets or bombs, the Typhoon proved very effective against ground

targets throughout occupied Europe.

My model represents a rocket-laden Typhoon Mk.1B

poised to strike German targets in France on D-day. This particular

aircraft belonged to No. 609 Squadron flying from Thorney Island in the

UK (see photo on pg 16 of Warpaint #5). Like many early rocket carrying

Typhoons, this aircraft had a three bladed propeller.

MDC’s 1/32 scale Typhoon Kit

In 2005, MDC released its first complete model kit

in the form of a resin 1/32 scale Typhoon Mk.1B with teardrop canopy,

tempest tailplane, and optional spinner/propellers (3 or 4 blade).

Since that time MDC has released a resin 1/32 Ki-61 Tony, and is set to

release a resin 1/32 Arado Ar.234.

The MDC Typhoon kit features numerous subassemblies

molded in light grey resin with finely engraved panel lines. The kit

also contains metal landing struts, a vacuform canopy, and decals for

several schemes. The detailing on the resin parts is superb, and the

fit is like what one expects from a mainstream injection-molded kit.

The fact that this kit is resin should not deter modelers interested in

building a large scale Typhoon. However, it is not cheap and some

building experience is required. The instructions are a let-down

because they are vague and difficult to read. I ended up downloading

images taken by those who built the kit before me in order to make sense

of the finer details of assembly, particularly for the cockpit.

However, the main aspects of assembly are obvious and straight forward

to someone familiar with building aircraft models.

Cockpit

Construction begins with the cockpit…..I found this

out when I sat down to start the kit and realized that the cockpit was

missing from my kit! My email to MDC was answered in very short order

and a replacement cockpit was sent to me at no charge within days

(thanks Bob!). Excellent customer service by MDC, particularly given

that a year and a half had passed since I purchased the kit.

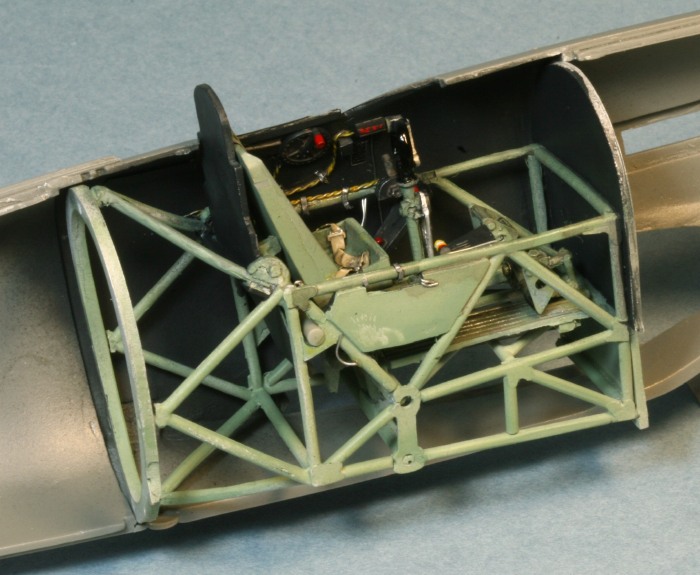

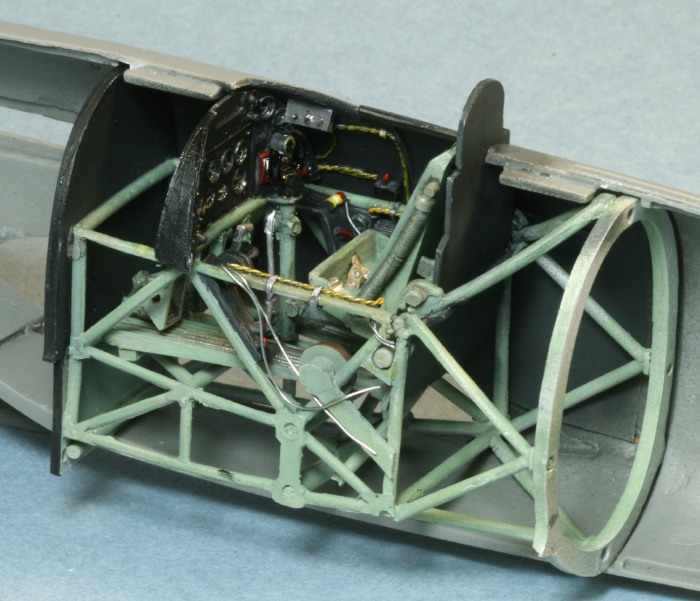

The cockpit consists of several panels of tubular

framework, a floor panel, seat, control stick, rudder pedals, and

bulkheads. A minimum amount of cleanup was required for the parts. I

added some wiring and switches etc for the upper cockpit sidewalls since

these were bare in the kit.

I opted to paint the tubular framework RAF interior

green, and the sidewalls, armor plate and headrest black. Some

references suggest the entire cockpit should be black, whereas others

suggest the tubular framework should be natural metal.

In any case, there’s not much to see of the cockpit

once the fuselage halves are glued together.

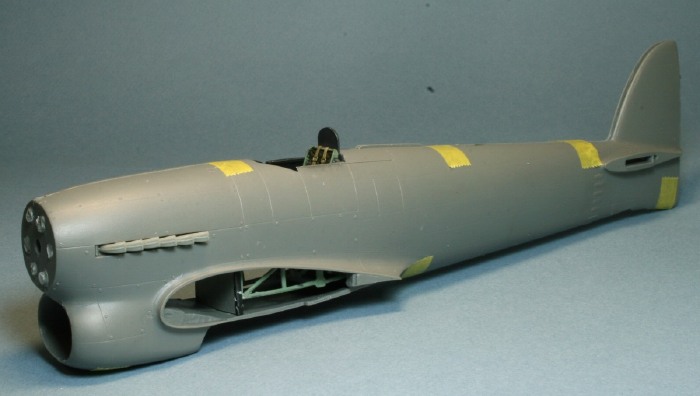

Fuselage

Before gluing the fuselage halves together, be sure

to add the exhausts and radiator details.

Although gluing the fuselage halves together

presented no (apparent) difficulty, several days later I noticed that

the tail leaned starboard, throwing the model’s alignment completely out

of whack. This error may have been a consequence of misalignment when I

glued the fuselage halves together (i.e., my fault), or perhaps the

parts were warped from the outset (i.e., not my fault). In any case,

the real question was how to fix the problem. I decided to remove the

tail (above the horizontal stabilizers) and add a styrene shim on the

starboard side to straighten the tail out. The tail was then reattached

with CA glue, and the seam was carefully filled and sanded smooth. It

may seem like major surgery, but the entire process took about 20

minutes and made a huge difference to the look of the model.

Click on the thumbnails

below to view larger images:

[../../photogallery/photo00014929/real.htm]

Undercarriage

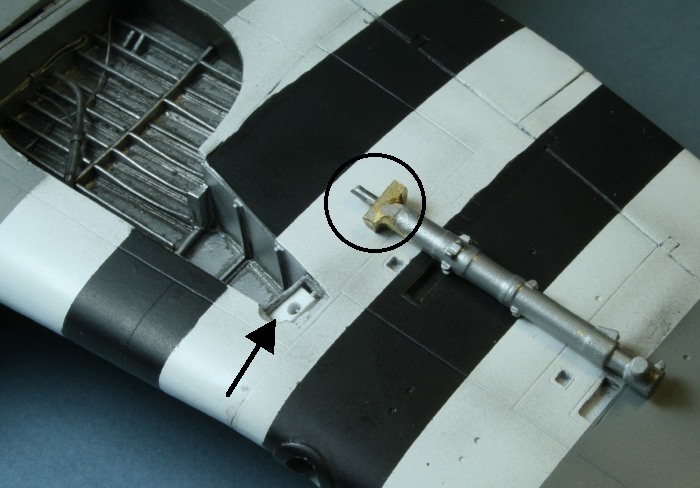

When dry-fitting the struts and wheels I got the

distinct impression that the model would sit low at the nose if I

positioned the struts at their proper forward rake. Indeed, the model

sat 8 scale feet at the tip of the spinner (on unweighted tires), but

drawings in the Warpaint book (modified from originals by A.L. Bentley)

indicated that the aircraft should sit about 9 feet high. To fix this

problem I added a small piece of styrene to the rectangular well that

holds each strut (see arrow in photograph). These pieces of styrene

extended the struts enough to raise the nose to its proper height. I

added a metal pin to each strut (see circle) to give the strut greater

stability when plugged into the well. I then used 5 minute epoxy to

glue the struts in place. The extended setting time of the glue gave me

time to ensure the struts were properly positioned.

I set the rake of the undercarriage using the

drawings in the Warpaint book as a guide. According to the drawings

(and photos), the rear part of the gear door’s lower edge should be

more-or-less horizontal with the ground. In many models this part

slants upward to the rear, indicating that the struts are not raked

forward enough.

Also, with proper rake, the center of the wheel hub

should align vertically with the rear of the second exhaust stack.

Wings

MDC provides separate wing flaps with lots of

internal detail – ideal for displaying the flaps in their dropped

position. However, I couldn’t find any photographs showing a parked

Typhoon with its flaps dropped, so I opted to leave mine raised. In

doing so there were some large gaps to fill with strip styrene and putty

along the edge of the flap where it meets the wing. My guess is that

the flaps were designed to be displayed down, not up.

The wheel wells are well detailed and the wings fit

solidly into the fuselage. I faired over the light on the leading edge

of each wing, something that most modelers miss when building a rocket

carrying Typhoon. According to Thomas (Warpaint #5, pg 25), and backed

up by photos, the wing lights on rocket-carrying Typhoons were faired

over because of fear that the Perspex would catch fire from the

rockets. Some later Typhoons apparently had a single wing light. Check

your references.

Although MDC supplies clear resin for the wingtip

lights, I opted to make my own from clear sprue. A hole was drilled in

the back of each wingtip light so that I could add a drop of Tamiya

clear red (port light) or green (starboard light).

Canopy

I was not impressed by the canopy that comes with

the kit (the framing was soft and vague) so I replaced it with one from

Squadron. Kent Eckhart provided the canopy I used – Thanks Kent, I hope

I can find you a replacement!

Rockets and Rails

MDC does not supply the rocket assembly with their

kit, so you will have to order it as a separate item. Some of the rails

in the set I purchased (item CV32023 - high explosive rockets) were

warped, but I corrected the problem by placing the rails in near-boiling

water and straightening them out. I used fishing line with a dollop of

white glue on the end to simulate the electrical firing leads.

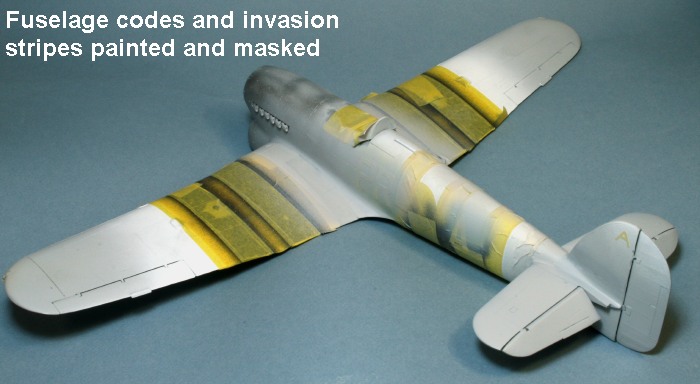

I painted and masked the fuselage tail band and

codes using Tamiya RAF Sky (XF-21). I then painted and masked the

invasion stripes using Tamiya White primer and Polly Scale black (with

some grey added). Note that the invasion stripes on this aircraft had

rough edges, and that the black stripes did not extend over the upper

half of the fuselage.

I painted the camouflage with Xtracrylix RAF Ocean

Grey and Dark Green over Medium Sea Grey. Although not shown in the

photo, the rear decking beneath the canopy was eventually painted

black. The wheel wells were painted with Alclad II duraluminum. The

spinner was first painted duraluminum and then scale black. I lightly

sanded the rear edges of the spinner to expose some of the aluminum.

The serial number for this aircraft is known only

as far as the MNxxx block. I mixed and matched numbers from the MDC

decal sheet to create MNx30. My decals for the fuselage roundels were

slightly out of register so I used spares from an Aeromaster sheet.

Exhaust stains were airbrushed on using highly

thinned black Polly Scale acrylic.

A wooden cutting board was used as the base for the

model. Celluclay was used to make the basic ground cover. The

celluclay powder was mixed into a paste with water and white glue,

tinted with brown acrylic paint, and then spread thinly over the cutting

board. Note that the cutting board had previously been treated with

several coats of clear lacquer to prevent warping while the celluclay

dried. While the celluclay was still wet I added pieces of Heki grass

mat (item # 1574 - Wild Grass Savanna) and fine sand. Heki products are

available for purchase in the United States from “Scenic Express”.

Outdoor images were taken with a Nikon Coolpix 5400

digital camera. The “unsharp mask” tool of Adobe Photoshop was used to

restore some of the clarity and crispness lost during image

compression. The “blur” tool was used to help merge the base with the

natural background. Indoor construction shots were taken using a tripod

with a Canon EOS 30D fitted with a macro lens.

-

Scutts, J. 1990.

Typhoon/Tempest In Action. Squadron/Signal Publications.

-

Shores, C. & C.

Thomas. 2004. 2nd Tactical Air Force, Volume 1:

Spartan to Normandy. Classic Publications.

-

Thomas, C.

Warpaint Series #5: Hawker Typhoon. Hall Park Books.

Click on the thumbnails

below to view larger images:

[../../photogallery/photo00011839/real.htm]

Model, Images and

Text Copyright © 2007 by Ian Robertson

Page Created 21 September, 2007

Last Updated 24 December, 2007

Back to HyperScale

Main Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |