|

Northrop YF-23

Collect-Aire Models, 1/48

S

u m m a r y

|

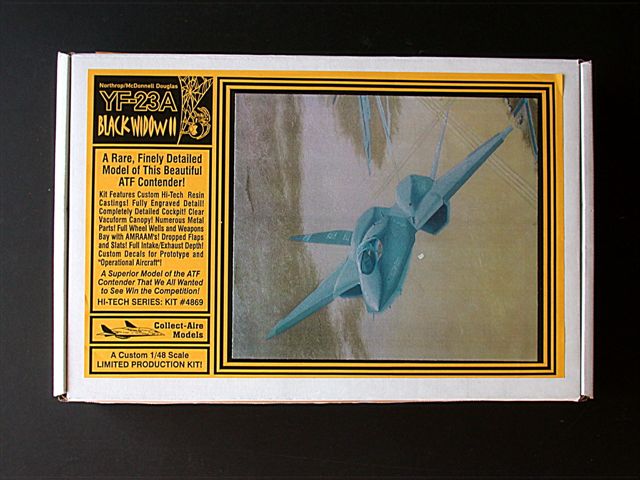

| Catalogue Number: |

Collect-Aire Models Kit #4869 -

Northrop YF-23 |

| Scale: |

1/48 |

| Contents and Media: |

Cream-colored resin; 2 vac-formed parts; decals for two

prototypes plus hypothetical operational aircraft |

| Price: |

USD$209.95

available online from http://collectaire.com |

| Review Type: |

FirstLook Plus |

| Advantages: |

Neglected

subject; good detail; high quality castings; impressive

size; |

| Disadvantages: |

Instruction diagrams are lacking;

righteous bucks required to buy the kit |

| Recommendation: |

Highly Recommended to modellers with

some experience working with resin kits. |

Reviewed by

"Bondo" Phil Brandt

HyperScale is proudly supported by Squadron.com

Although the Northrop YF-23 “Black Widow II” is best known as runner-up

to Lockheed-Martin’s YF-22 “Raptor” in the high stakes 1990 Advanced

Tactical Fighter (ATF) flyoff, even today there is a contingent of aviation

fans that maintain that the YF-23 was not only more esthetically pleasing

than the Raptor, but was a superior performer. Test pilots who flew the

YF-23 have remained suspiciously tight-mouthed about the relative merits of

Northrop’s entry, so we might not know for years the political infighting

that led to the DOD selection.

Over the past six decades the innovations of Northrop Aviation–Donald

Douglas once said that every aircraft in the world had a part of Jack

Northrop’s genius in it--have suffered some most unfortunate non-selections

by the USAF: the cutting edge XB-35 and YB/YRB-49 flying wings, a concept

vindicated fifty years later by the B-2, and the more recent F-20 Tigershark,

a stunning high performance, single-engine conversion of the very successful

F-5.

Kit Chronology

Largely because of its real world non-selection, this is a little-done

bird; the only previous release is the 1/72 Testors injected kit of at least

ten years ago. Not a bad effort at all, but when Collect-Aire released the

big–in 1/48 this airframe is larger than either the F-15 or Flanker–Black

Widow II in resin, this curmudgeon had to have one.

As a battle-hardened owner-builder of many Collect-Aire releases I freely

accept the idiosyncrasies seemingly endemic in its eclectic, bigbuck lineup

of subjects. As in the case of the recently-reviewed Collect-Aire B-45, this

kit also seems at first look to not have as many problems as releases of the

past. Besides, who else ya gonna call to do this esoteric subject in 1/48?

Tamiyagawa is still busy recreating what seems like every version of every

WWII fighter extant, and Trumpeter has bigger–literally– fish to fry with

its most welcome foray into developing 1/32 Century Series kits.

Molding

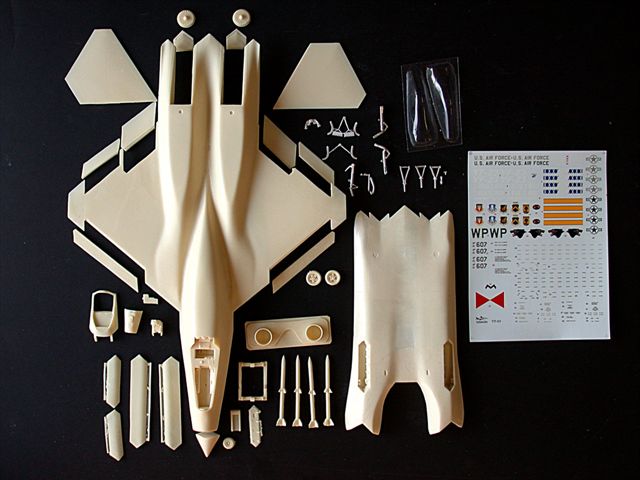

This is a simply-engineered kit; the fuselage top and complete wings are

one monolithic chunk of (hollowed-out in the main fuselage) resin. The

bottom fuselage is also a very large casting and embodies the engine

intakes, complete with deep, cast-in trunking that runs way back to the

compressor faces. The surface is very smooth, much like that of the recently

released B-45. I found no bubbles, but this is not to say that there are no

surface problems. The wingtop surfaces have obvious manufacturing sanding

marks, and there’s a surface discontinuity on the right wing. That is, the

outer wing is a thousandth of an inch or so thinner, and is defined by a

chordwise line that extends from the leading edge all the way back to the

flap. This will need to be block sanded, and I suspect that’s what happened

to the left wing also. The thickness discrepancies may be the result of

successive resin pours into the large top fuselage mold. The bottom fuselage

has one small area that is exceeding thin, so much that it’s almost

translucent and bears the look of a casting “fix”, that is, there’s a glossy

resin layer on a major area of the inside surface whereas the rest of the

casting has the same semi-gloss texture as the rest of the airframe.

Click the thumbnails below to

view larger images:

[../../../photogallery/photo00016022/real.htm]

Fuselage

Monolithic resin pours almost guarantee differential shrinkage of

adjoining components and, thereby, fit problems. The main difficulty is

getting the upper and lower fuselage halves to mate accurately so that the

cast-in intake trunks line up all the way back to the compressor faces, and

the stealthy zig-zag aft fuselage “tailfeathers” align at the same time.

This process took mucho Dremel work, hours in fact, and the intakes are

still not lined up completely. While casting the intake trunk channels in

upper and lower fuselage halves may sound like a neat idea, filling,

smoothing and painting the said trunk seams along their long (four inches)

join lines is going to be tough, so much so that I might have to opt for

intake covers. If not, good luck on working the seams back through a

3/4-inch cross section! Where’s Seamless Suckers when ya really need ‘em? In

fairness, though, the only way poorly finished seams will be visible, is if

one peers up into the intakes, and most everyone will be looking downward at

some angle. Nobody said modeling would be fair......

Wings

Integrated with the upper fuselage, the clipped triangle-shaped wings are

real chunks of resin, albeit well done, with sharp trailing edges. The

leading edge slats and the flaps and ailerons are separate and may be posed

in various deployed configurations.

Tail Surfaces

The two large, outwardly splayed tail fins (fifty degrees) are one-piece

with, again, nice, sharp trailing edges. The fins simply butt-join to

pre-angled aft fuselage strips, but I plan to use brass tubing so that the

joint is more substantial and so that the fins may be slightly canted from

neutral to simulate what often happens when a fighter’s hydraulics are off.

Engines

We’ve already covered the intake trunk layout, and the hidden exhaust

outlets are represented by two plain exhaust cylinders integrated with a

rear fuselage former.

The cans are deep enough that the builder may not have to scrounge up a

couple of parts bin turbine faces.

Cockpit

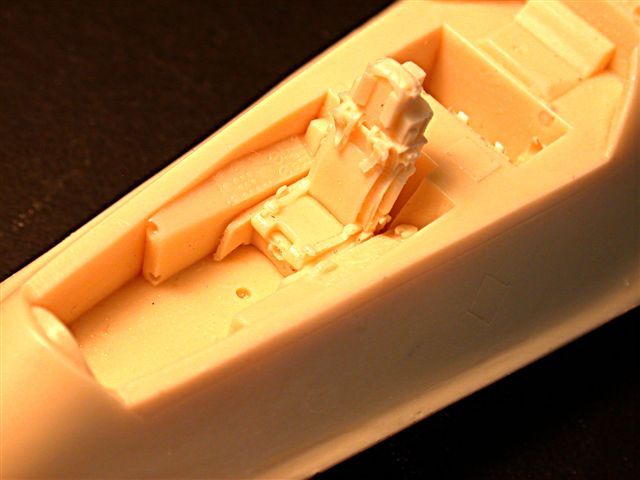

The cockpit tub in integral with the monolithic upper fuselage casting

and has decent–we’re of course not talking Avionix or Aries here–raised

detail on side consoles. A separate center console fits into a cast metal

multifunction display instrument panel. The instrument panel nests in the

separate resin windscreen coaming. The Aces II seat is well done, if

relatively plain, with cast-in harness and belts. It seems to me that some

aftermarket seats may have more detail.

The control stick for the fly-by-wire system is done in cast metal, and

there is a separate metal cockpit raising assembly and some type of

avionics/air-conditioning detail provided behind the seat.

Clear Parts

Two vacuformed canopy/windscreens are provided. They’re appropriately

thin, but both have slight surface “frosting”-- I don’t know if

Future-dipping will save the day– and some small surface bumps which,

fortunately, can be fixed since they’re on the canopy surround rather that

the canopy clear portion. The canopy’s aft edge (that mates with the

fuselage when closed) is in the shape of three “teeth” (to maintain radar

stealthiness), and here the vacuforming could have been better accomplished

because the toothed edge is too close to the end of the vacuform master,

making the whole area rather indistinct and not as crisply shaped as the

rest of the canopy.

A welcome kit feature is that Collect-Aire has chosen to include a

substantial resin canopy frame assembly. This is especially important to

advocates of open-canopy models. Unfortunately, the frame’s front “bow”

isn’t quite parallel to the slant of the canopy/windscreen mating line, and

the builder will have to judiciously apply hot water to bring the resin bow

into alignment.

Landing Gear

Sturdy, crisply molded, two-piece metal main and nosegear struts will

easily carry the weight of this hefty airframe. Resin wheel/tires have

decent detail.. Maingear wells are, well, somewhat detailed, if you can call

a strut mount and five strips of Evergreen square stock applied to the side

of each well detailed. The nosegear well is completely unadorned. The

maingear doors are plain and have clunky-looking lengthwise “bars” to act as

hinges. I’ve never seen detailed closeup pix of said airframe, but the whole

deal looks hokey, and I’ll probably cut off the bars and fabricate two or

three hinges from plastic stock. The nosegear door has some inside detail

and four normal-looking hinges.

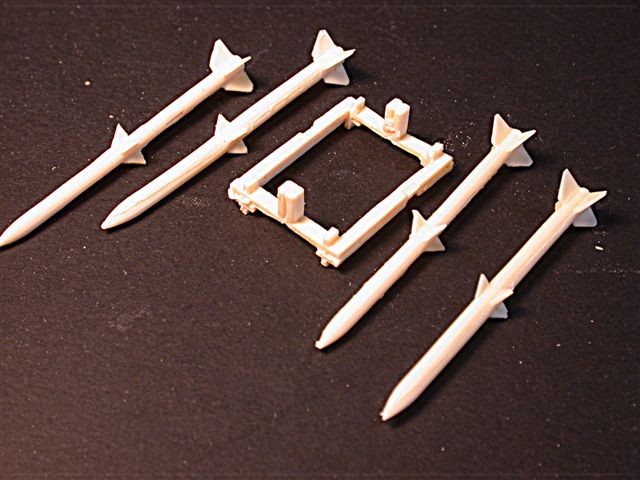

Weapons

As with the Raptor, weapons are carried internally. Collect-Aire

furnishes four AMRAAMs, a resin launcher assembly and cast metal bay door

hinges and air deflectors. Even though the bay parts and surface detailing

are welcome, in the end I decided to configure the bays closed because when

posed open on the ground, I believe they significantly detract from the

overall sleekness of the airframe design.

Gluing the bay doors closed required lots of fitting and plastic stock

support along the center join line of the doors.

Decals

Thin, with excellent color registration.

The modeler has the choice of markings for not only either of the two

prototypes but also for a hypothetical scheme (my personal favorite) from

the South Korea-based 8th Tac Fighter Wing “Wolfpack.” Command, wing and

squadron logos are especially well-done, as are the wolf’s heads located on

the fins. I’m guessing that talented Gerry Asher, honcho of Ft. Worth’s Fox

3 Studios must’ve done the decal design–he has painted many Collect-Aire box

art originals, including this one–because one of the many stencils reads

“C/C: SSgt P.G. Asher.”

Instructions

A twelve-page pamphlet details the history of the bird and includes

simple assembly parts ‘blowups” which in this case are OK because there

aren’t many parts. Also provided are full-page planform and profile drawings

of all three versions with good color callouts and shapes, as well as the

locations of the copious markings/stencils.

A sleek, menacing design that deserves a place in every 1/48 modeler’s

stable of current aircraft. You might have to take a gentle face slap or two

during construction, but certainly not a resin “beating.”

Review Text and Images Copyright © 2006 by

Phil Brandt

Page Created 13 December, 2006

Last updated 24 December, 2007

Back to HyperScale Main Page

Back to Reviews Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |