|

Mitsubishi G3M Nell

Koster Aero Enterprises, 1/48 scale

S

u m m a r y

|

| Catalogue Number: |

Koster Aero Enterprises Model Kit No

KEA 30 - Mitsubishi G3M Nell |

| Scale: |

1/48 |

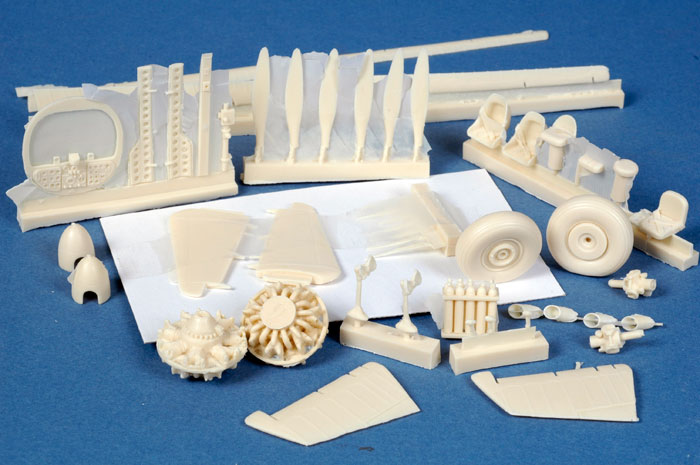

| Contents and Media: |

28 vacuum formed parts in white and

clear styrene; 49 cast metal parts; 60 cast resin parts; markings for

three aircraft |

| Price: |

USD$69.95, available via email

direct from Koster Aero Enterprises

wkoster2@comcast.net

or online from Great Models

Webstore |

| Review Type: |

FirstLook |

| Advantages: |

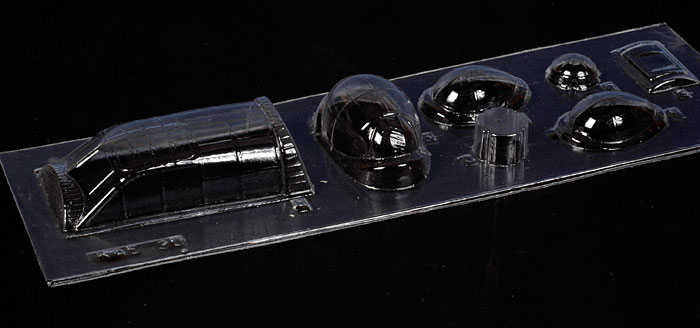

Excellent decals; crystal clear vac

formed transparencies; good surface detail; crisply cast resin and metal

parts; three colour scheme options; clear instruction sheet detail |

| Disadvantages: |

Vac form (but not really a

disadvantage if you are an experienced vac form builder); no history

details on colour schemes |

| Recommendation: |

Recommended |

Reviewed by

Mick Evans

HyperScale is proudly supported by Squadron.com

The new vacuum formed release from Koster Aero

Enterprises of the World War II Japanese twin engine torpedo bomber the

Mitsubishi G3M Nell is a welcome release in the 1/48 scale arena. The

kit contains 28 vacuum formed parts in white and clear styrene, 49 cast

metal parts, and 60 cast resin parts. Markings are provided on a decal

sheet covering 3 different schemes.

Click

the thumbnails below to view larger images:

[../../../photogallery/photo00023581/real.htm]

The kit parts are typical of previous high

quality multi-media kits manufactured by Koster.

The vacuum formed parts are crisply formed with

good panel detail. The interior cockpit side walls, bulkheads and floors

are vacuum formed. At first I was skeptical as to whether the detail

would be replicated crisply enough in vac form but on closer inspection

I was pleasantly surprised, and once the metal and resin parts are added

the area will look very busy and well detailed. The only challenge that

I could foresee with the vac formed parts is the elevated platform for

the upper waist gunner position has been stretched to the limit in the

moulding process and will need to be reinforced with plastic card to add

some strength, but for most vac form builders this is barely a

challenge. Two vac formed wing spars are provided to give a firm

mounting point and sets the wing dihedral correctly.

Assembly starts with the assembly of the interior

fit out. This involves the fitting of the vac form side walls and wing

spars. The cockpit is built up with vac formed floor and rear bulkhead.

The front bulkhead which includes the instrument panel is cast crisply

in resin. To this assembly are added the resin pilots and navigators

seats. The controls are a mix of resin and metal parts.

The build up of the rear fuselage is a similar

build with a mixture of vac form, metal and resin parts. The

instructions make mention of fitting 4mm x 5mm reinforcement tabs cut

from the spare vac form plastic to the inside of the fuselage seam line

as a method to increase the strength of the join. Having built quite a

few vac form kits this is a mandatory part of construction and can avoid

a seam failure on the completed kit.

One the fuselage is full assembled I would

suggest fitting the vac form transparencies. This has two advantages,

the first is that it prevents the ingress of dust into the fuselage and

the second advantage is that it allows for easy access to blend the

transparencies to the fuselage.

Once the fuselage is completed assembly can

commence on the wings and tailplane. These are constructed from vac form

parts including the wheel well ceiling and lower engine nacelle

mounting. These can be then attached to the fuselage. The two vertical

fins and rudders are cast in resin and attach cleanly into slots cut in

the horizontal tailplane.

The engines are beautifully and crisply cast in resin with separate push

rods cast in metal to be fitted to each cylinder. Once the engines are

built they are installed into the vac forme nacelle cowls. The cast

resin exhaust stubs are the final part of this assembly.

The undercarriage is crisply cast in metal with

resin wheels and undercarriage doors. These parts locate into mounting

holes drilled into the wheel well ceiling. The propeller is constructed

from a resin hub with individual resin blades. Once assembled a resin

spinner is installed before fitting the assembly to the engine.

Full length resin flaps are provided along with

seven resin hinges and two balance horns. These should attach easily to

the underside of the wing surface. The torpedo is made from two vac

formed halves with the fins and propellers being constructed from

plastic card using the templates provided on the instruction sheet.

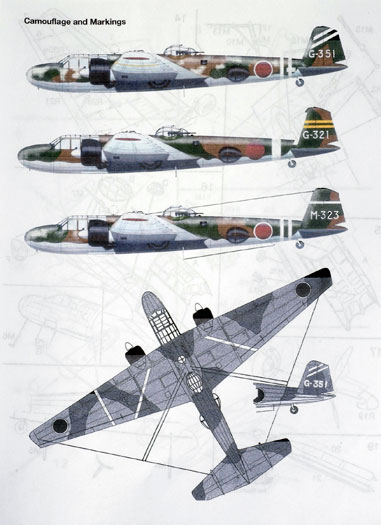

Colour schemes are for three aircraft in light

grey undersides with dark green and dark brown upper surfaces. The

decals are crisply printed with good colour saturation and thin carrier

film.

The instructions are easy to follow, while the

colour schemes are presented in colour but give no details as to unit

markings where the aircraft operated or the period of operation. These

details are nice to have and make researching the particular aircraft a

bit easier.

Overall this looks to be a beautiful kit and will

sit very nicely beside my Tamiya Betty and Dinah when complete.

Recommended for modellers of above average skill and experience.

Thanks to Koster Aero Enterprises for the sample

Review Text Copyright © 2007 by Mick Evans

Page Created 02 October, 2007

Last updated 24 December, 2007

Back to HyperScale Main Page

Back to Reviews Page

|

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |