Martin-Baker MB.4 Bubbletop

Aerocraft Models, 1/48 scale

S

u m m a r y : |

Description and Item No.: |

Aerocraft Models Kit No. ACMK4804 - Martin-Baker MB.4 Bubbletop |

Contents and Media: |

52 parts in grey 3d printed resin; four clear resin parts; decal sheet; instructions. |

Price: |

£50.00 Plus Shipping from Aerocraft Models |

Scale: |

1/48 |

Review Type: |

First Look |

Advantages: |

Cleanly printed parts; smooth surfaces; subtle surface textures including recessed panel lines and rivets; high level of detail; useful options including stinger rudder for Royal Navy version, slick or diamond tread tyres, poseable canopy, armed or unarmed wings, optional harness straps printed direct onto the seat; interesting subject choice; stout packaging; includes decals and vinyl masks. |

Disadvantages: |

Some experience with short-run kits may be helpful. |

Recommendation: |

This is a really cleverly designed and executed kit of an intriguing "what if" subject. Recommended. |

Reviewed by Brett Green

Background

By the late 1930s, the Air Ministry’s fighter landscape was dominated by the Spitfire and Hurricane, with the Typhoon and Tornado on the drawing board. Into this competitive, politically fraught environment stepped James Martin and Captain Valentine Baker, a partnership of extraordinary imagination and engineering conviction. Their Martin-Baker company was small—almost a cottage concern compared to Hawker or Supermarine—but their ambition was anything but modest.

The MB.3 was conceived as a rugged, heavily armed fighter, designed around the philosophy of simplicity in construction and ease of maintenance. Powered by the Napier Sabre—a notoriously temperamental engine—it was a purposeful, pugnacious machine, with wide undercarriage, strong lines, and no fewer than six 20 mm Hispano cannon in the wings. For 1942, this was a ferocious armament fit, well in excess of a contemporary Spitfire Mk.V or Bf 109G.

The prototype, R2492, took to the air in August 1942. By all accounts, Captain Baker was impressed with the MB.3’s handling: stable, responsive, and powerful, with excellent visibility thanks to a clean cockpit layout.

Tragically, disaster struck on 12 September 1942 when the engine seized during a test flight. Baker attempted an emergency landing in a field, but the MB.3 overturned and he was killed. The accident was devastating—not just to the company, but personally to Martin, who lost both his closest friend and test pilot. From that moment on, Martin became obsessed with pilot safety, a determination that would ultimately lead to Martin-Baker’s lasting legacy: the ejection seat.

Despite the setback, the Air Ministry saw promise in the design, and development shifted to the MB.4. On paper, this was an evolution of the MB.3, retaining the clean lines and heavy armament but substituting the troubled Sabre with the Rolls-Royce Griffon. The Griffon promised greater reliability and was already earmarked for later marks of Spitfire, but delays in engine supply meant that the MB.4 never progressed beyond design studies and mock-ups. With official interest waning and Martin’s focus increasingly turning to safety systems, the MB.4 quietly faded from the scene.

It is tempting to imagine what might have been had the MB.3 gone into production. A Griffon-powered, six-cannon Martin-Baker fighter entering service in 1943 would have been a formidable opponent for the Focke-Wulf 190 or Messerschmitt 109G. Instead, the company pivoted away from building complete aircraft and carved out its place in aviation history as the name synonymous with ejection seats—an innovation that has saved more than 7,600 lives worldwide.

The MB.3 and MB.4 stand as milestones in the Martin-Baker story: the final attempts to enter the competitive fighter arena, and the tragic catalyst for a new mission that would save lives rather than risk them. In many ways, the failure of these fighters was the making of Martin-Baker, setting the company on a path where its legacy would outshine even the most successful wartime aircraft.

Modelling the Martin-Baker MB.3 and MB.4

The MB.3 has never enjoyed the mainstream coverage of Spitfires or Mustangs, but it has popped up in kit form from time to time, usually from short-run or cottage industry producers. These kits tend to reward patience, good references, and a willingness to reach for filler and sanding sticks.

- 1:72 scale: Rareplanes produced a vacform MB.3 many years ago, and Pegasus followed with a short-run injection kit. Both require care, but capture the bulky lines of the aircraft convincingly.

- 1:48 scale: Czech manufacturer Pegasus (not to be confused with the earlier brand) offered a limited-run kit, while Magna released a resin MB.3. These are the most accessible routes in quarter scale, though expect soft detail and plenty of clean-up.

- 1:32 scale: No mainstream kits exist, though the subject has occasionally tempted scratch-builders and resin garage projects.

Pickings are even slimmer for the MB.4. No mainstream kits have ever been released.

For modelers, the MB.3 has always held an aura of “obscure but appealing.” Yet there is something compelling about those lines—the purposeful nose, the broad wings, the sheer bulk of the thing. It’s an aircraft that looks like it means business, even if fate conspired against it.

Aerocraft Models has released a family of Martin-Baker MB.3 MB.3b and MB.4 full 3d printed resin kits in 1:72 and 1:48 scales.

When Aerocraft supremo Ali asked if I would like to build one of these I did not hesitate. I particularly liked the streamlined lines of the hypothetical MB.4 powered by the Bristol Centaurus radial engine. The 1:48 scale kit arrived today, and it is certainly impressive.

Aerocraft Models’ 1:48 scale Martin-Baker MB.4 comprises around 52 parts in grey coloured 3d printed resin, four parts in clear resin, laser printed decals, vinyl canopy masks, an A4 colour artwork and instructions.

The proof is in the printing as far as 3d resin kit are concerned. The printing of my sample is perfect – smooth surfaces and absolutely no visible striations or other printing imperfections, even under the magnification of my Optivisor.

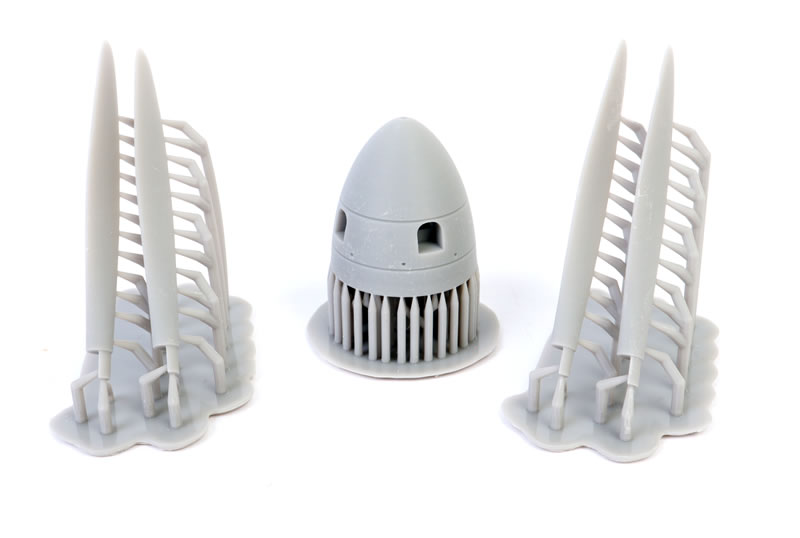

The lattice pattern attachment points look a bit scary but most of the structure is not actually connected to the fuselage. I am sure that clean-up will not be a major chore to anyone who has built a 3d printed kit before.

The fuselage is printed as a single part with the rudder, horizontal stabilisers and the engine cowling being separate. The mid-top fuselage is designed with a separate saddle that allows the cockpit to be dropped in.

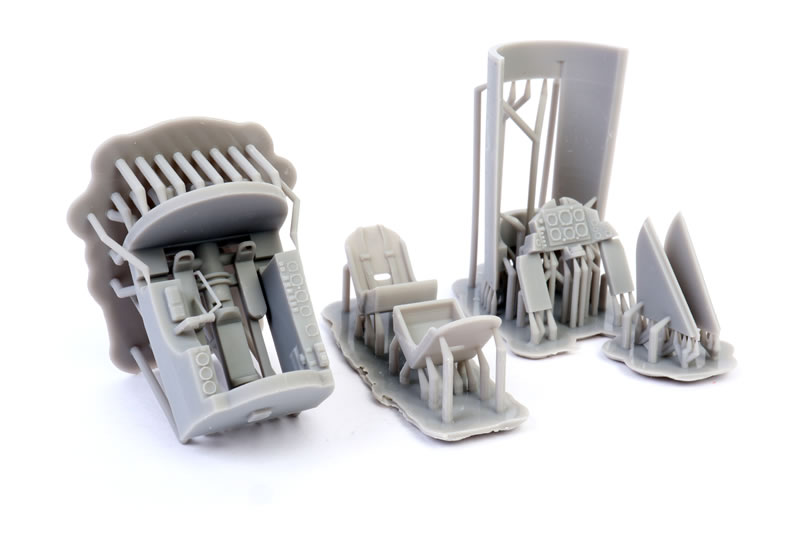

The cockpit is well detailed starting with the one-piece cockpit tub and integrated side consoles, foot rests and rudder pedals.

The separate instrument panel has raised bezels and switches that will benefit decal dials or careful painting.

Two pilot’s seats deliver the choice of harness straps or no harness straps. I’ll be using the one with the harness.

The control column is a separate part and it appears that a spare is included.

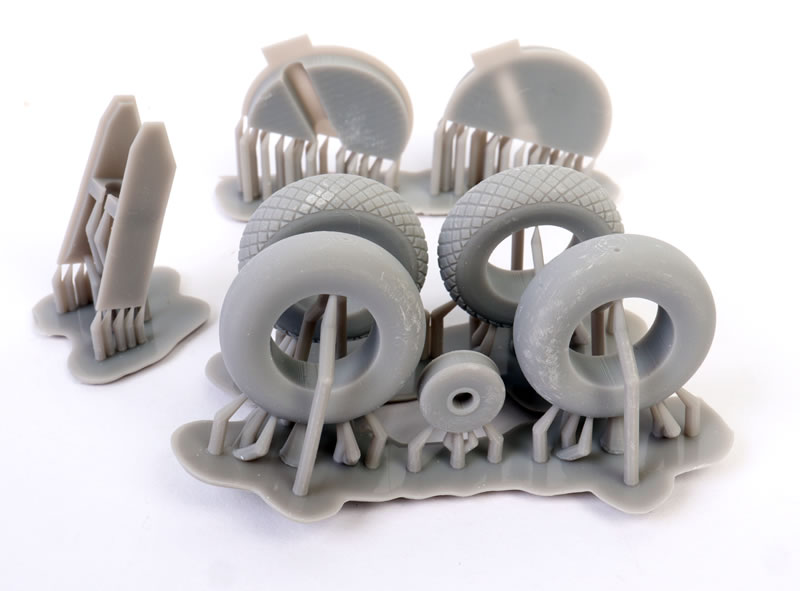

Wings are printed as one side each. Recessed wheel well detail looks good. A stout locating point with a vertical slot is printed into each wheel well to ensure a precise and robust fit for the main undercarriage leg. The legs are printed with a corresponding vertical tab.

The main undercarriage legs are printed in darker grey resin, presumably stronger than the standard stuff. Each is printed with the outer wheel hubs, oleo scissors and retraction struts in place. This should make installation of the undercarriage legs a breeze.

Upper and lower undercarriage doors are included. The anti-shimmy tail wheel looks good too.

Aerocraft has designed the wing with a separate insert at the leading edge for either unarmed version or two guns in each wing.

Aerocraft offers the choice of either slick tyres or diamond tread.

The rudder, horizontal stabilisers and elevators are separate parts. Optional rudders are offered. One is printed with a stinger tail hook for Royal Navy carrier operations. I like the fine raised horizontal lines on the rudder.

The four-part Centaurus engine looks great with two rows of cylinders, exhausts and a one-piece close engine cowling. Engine detail is wonderful - crisp cooling fins, cylinder head detail, manifold pipes and crankcase. No short cuts here!

The spinner is printed as one piece with nice deep locating holes for the four propeller blades.

Four clear resin parts are supplied. The windscreen canopy sliding section are smooth and free from distortion. The wing tips are 3d printed clear resin. They are a bit cloudy but a quick dip in Future Floor Polish (or your local equivalent) should fix that quick smart.

Aerocraft has also thoughtfully supplied vinyl masks for the windscreen and sliding canopy section.

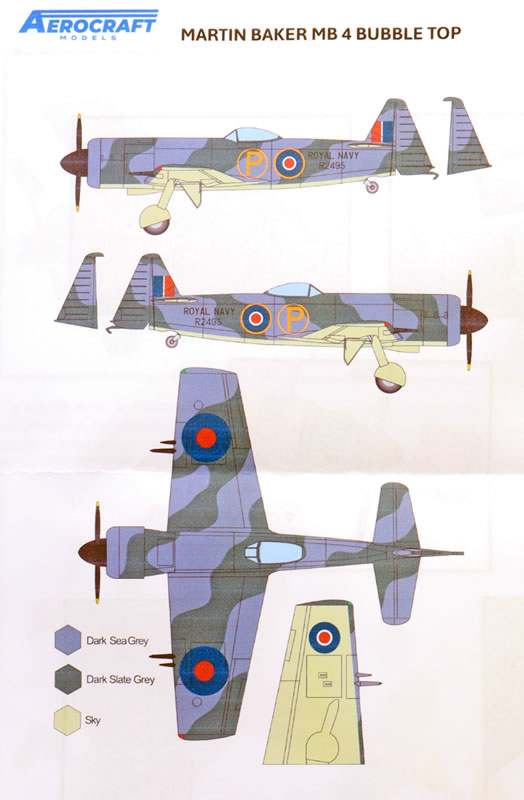

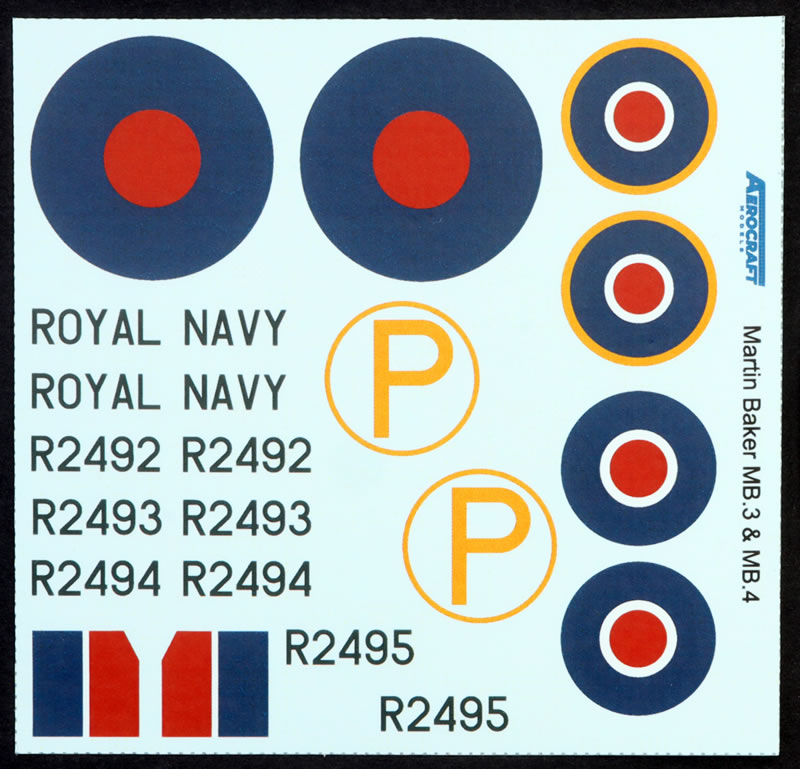

Laser printed decals are supplied with a single set of Type B upper wing roundels and Type C roundels and fin flashes, plus a set of prototype roundels, Royal Navy lettering and five sets of serials.

Instructions and a colour guide (completely conjectural of course) round out this classy package.

Aerocraft Models’ 1:48 scale Martin-Baker MB.4 is a beautifully executed package of a subject that most of us would never have expected to see in kit form.

The quality of the 3D printing is outstanding, the engineering is clever and practical and the details – from the Centaurus engine through to the clear parts and decals – make this a genuinely complete offering straight from the box.

Add in options like wing armament, rudders, and tyres, and you have all the ingredients for an impressive build.

For anyone with an interest in British prototypes, radial-engine “might-have-beens,” or simply the desire to try their first-class 3D-printed resin kit, Aerocraft’s MB.4 is a highly appealing project.

This is an impressive debut for MB.4 in 1:48 scale. It deserves a place on the bench of any modeller looking for something out of the ordinary.

Thanks to Aerocraft Models for the sample

Text and Images Copyright © 2025 by Brett Green

Page Created 5 September, 2025

Last updated

6 September, 2025

Back to HyperScale Main Page

Back to Reviews Page |

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search