|

|

|

F-14A

Tomcat |

Hasegawa's

1/48 scale F-14A Tomcat and

Black

Box's F-14D replacement cockpit

are available online from Squadron.com

With apologies to Tom Cruise, the real star of the movie Top Gun is

the F-14 Tomcat. It is probably the most widely recognized and capable

Naval air superiority fighter of the modern era (my opinion, with

further apologies to all the Hornet lovers out there). With a design

dating back to the early Seventies, it remains one of the US Navy's

premier aircraft, even today.

The original Tomcat design was for a pure air defense fighter

employing long range Phoenix missiles to protect Carrier Groups from any

perceived aerial threat. Shorter range Sparrow and Sidewinder missiles

give the Tomcat close range armament. For the traditional dogfight, the

Tomcat is also equipped with the ubiquitous six-barrel Vulcan 20mm

rotary cannon. Later developments have introduced a reconnaissance role

to the Tomcat using the Tactical Air Reconnaissance Pod System (TARPS).

The most recent developments from the 1990s have now added ground attack

to the Tomcat's list of missions.

Hasegawa was quite late in releasing a Tomcat in 1/48th scale. Rumors

had been flying for years about them finally doing it. With a growing

line of F-4 Phantoms, A-7 Corsairs, and F-15 Eagles, it only made sense

that they would continue the line by including the F-14 Tomcat. Finally,

in the 1980s, a decade after the F-14 entered Fleet service, they

released a 1/48th scale kit.

This posting is another part in a multi-part posting on the Hasegawa

Tomcat. In this posting, I will describe the kits and discuss the issues

with constructing the kits. In future postings, I will highlight my

completed models of the Tomcat (I now have three) and discuss things

specific to each project.

The following are brief descriptions of a spattering of the earliest

releases that Hasegawa made on the F-14 Tomcat. This list is by no means

complete. I am only showing the roots of where the current Hasegawa

releases on the Tomcat are based. There have been numerous special

release kits with special decals for various aircraft, too numerous to

list them all. All these special release kits are just re-boxings of one

of the kits I list below. In some cases, like with the "Bombcat"

releases, the special release kits also include a few extra parts, but

the base kits remain unchanged.

|

This is the original box art of the original Hasegawa F-14 Tomcat

kit, an F-14A (stock #07018 / P018). The kit was released in the

early to middle 1980s. It featured a slew of in-the-box options

(which I list later in this posting) and five different Pacific

Fleet marked aircraft in the decals (VF-21 and VF-154 in two

versions, each, and a VF-111 CAG). |

|

This is the box art of the second Hasegawa F-14 Tomcat kit, another

F-14A (stock #07019 / P019). This release was only a few weeks after

the first release and contained an identical kit to the first one.

Only the decals were different. This time the kit featured four

different Atlantic Fleet marked aircraft in the decals (VF-31,

VF-74, and VF-84 in two versions). |

|

This is the box art of the third Hasegawa F-14 Tomcat kit, still

another F-14A (stock #07020 / P020). This release was only a few

months after the first two. This time the plastic components were

changed to represent an early block aircraft. The new components

replaced pieces from the earlier kit releases so that only an early

block aircraft can be built with this kit. To the current date, this

is the only Tomcat release with the components to build an early

block aircraft. The decals included both Atlantic and Pacific Fleet

markings (VF-1 CAG, VF-14, and VF-32 CAG). |

|

The F-14A+/B Tomcat was first released as a special release kit

(stock #51508 / SP008) with updated components to build an accurate

F-14A+/B Tomcat. The big change was the replacement of the P&W TF30

engine exhausts with the GE F110 engine exhausts. There were a few

other minor changes to the kit to complete the F-14A+/B. The decals

provided three low-vis aircraft (VX-4, VF-74, and VF-101). The box

art I have included here is actually the second release of an

F-14A+/B Tomcat as a standard stock kit (stock #07023 / P023). It

has the same plastic as the earlier special release kit, only with

new decals for three different aircraft (VF-74, VF-143, and VF-211

CAG). |

|

As the F-14D was just hitting Fleet service, this kit was released.

This is a special release kit (stock #51544 / SP044) with updated

components to build an accurate F-14D Tomcat. Decals were provided

for two aircraft (VX-4 and VF-124). The kit was based on the earlier

F-14A+/B Tomcat kit releases. All the pieces needed to make the

F-14D were just added to the F-14A+/B kit without removing the

counterpart pieces. Knowing which pieces to mix and match allows the

construction of accurate F-14A+/B or F-14D models from this kit. To

date, no standard release kit of the F-14D has ever been made. There

have been multiple special release kits, though, providing a variety

of decals options. |

Hasegawa's 1/48 Scale

Tomcat Described

|

Do you want the short version or the long one? Anyone that has ever

built (or tried to build) one of the Hasegawa 1/48th scale Tomcat kits

can attest to there being lots you can say about them -- both good and

bad.

The short version is this -- on the good side, the Hasegawa 1/48th

scale Tomcats are the most detailed and accurate Tomcats of any kits on

the market today, bar none. This is a strong statement, but in my

opinion, it is true. On the bad side, the kits are quite a challenge to

build due to their many complexities and fit issues. Over the years, I

have actually not seen many of these kits finished. If you ever try to

build one, you will find out why many have never been finished. I would

bet most end up broken after being thrown against a wall. You really

have to want to complete the kit to put up with some of the issues it

presents.

If you do not care to read all the gory details about building these

kits, you can back out of this posting now and wait for my future

postings that will show my completed Tomcats. Otherwise, read on...

I acquired my first Hasegawa F-14 kit when it was originally released

in the middle 1980s. It cost a whopping $60 back then and is still

generally in the same ball park for its price today. On the heels of

Hasegawa's very well done F-4 Phantoms and A-7 Corsairs, I was sure that

the F-14 kit would not disappoint me and plunked down a half-week's

salary (at that time) without any hesitation. The kit turned out to be a

mixed blessing.

The original two releases of this kit provide all necessary

components to build any F-14A from the middle of the block 75 aircraft

(starting with BuNo 159421) up through the last F-14A to be produced (a

block 140 aircraft, BuNo 162711). Re-releases of the kit with different

parts allow the building of earlier F-14A Tomcats (prior to BuNo 159421)

as well as F-14A+/B/D Tomcats and "Bombcats". The only Tomcats that

Hasegawa does not provide a kit for are the twelve prototype /

pre-production aircraft (BuNo 157980 through 157991). Over the years, I

have acquired many of these kits (I have expensive taste). Most

everything I write here about constructing these kits applies to all the

kits, collectively.

The kits provide all of the following right in the box. This is quite

a list by any standard.

-

|

Hasegawa F-14 Tomcat

Parts Trees

Click

Thumbnails below to view larger images:

Parts Tree A and B

Parts Tree E, H and K

Parts Tree C and F

|

- Finely engraved panel lines throughout the entire kit.

- Raised cockpit detailing. Through the use of separate insert

pieces, Hasegawa provides accurate instrument panels for each of

their Tomcat kits. They just substitute different instrument panel

pieces.

- Optional position boarding ladder and steps. The ladder is

constructed using etched metal pieces to form the vertical sides.

There are no plastic pieces in the kit to replace these metal

ones, so you must use these etchings if you intend to construct

the model with its boarding ladder extended.

- Very well detailed landing gear. The main landing gear legs

are each composed of nine-pieces. The nose landing gear leg is

made up of thirteen-pieces including alternate pieces to allow you

to "kneel" the aircraft as it would be seen for a catapult launch.

The only things that the legs are missing are some wiring

harnesses. Apparently, Hasegawa intended to leave the wiring

harnesses up to the modeler to add as super-detailing items.

- White metal wheel hubs with rubber/vinyl tires. Included in

most of the kits are alternate wheels with varying spoke patterns

to model the different wheels used across a wide range of Tomcat

production blocks.

- Complete, fully detailed wheel wells.

- Optional position swing-wings. In support of the optional

position wings, Hasegawa provides alternate wing glove bladders.

These bladders inflate and deflate as the wings sweep forward and

back. They fill the slot that the wings swing in and out of, thus

preserving the aerodynamics of the fuselage. The alternate bladder

pieces allow for either fully inflated bladders with the wings all

the way forward or fully deflated bladders with the wings in

over-sweep (as they would be while parked on the carrier deck).

The kit allows for the wings to be positioned at any sweep angle,

but the bladders would need to be reworked to whatever partial

inflation level they should be to fill the wing slot.

- Optional position wing flaps and leading edge slats. Attaching

the flaps in the lowered position does require the positioning of

the wings to be fully forward.

- Optional position horizontal tails.

|

- Optional position speed brakes on the top and bottom of the

"beaver tail". The speed brake wells are appropriately detailed with

the correct ribbing and contours.

- Optional position tail hook. Actually, if you build it right, the

tail hook is functional and can be raised and lowered on the completed

model. I do not build my models as toys, so I glued the tail hook in

the position I wanted it (raised).

- Optional open and closed engine exhaust nozzles with complete

afterburner interiors all the way in to the flame holders and

turbines. Even in the F-14A+/B/D kits with the new engine exhaust

pieces, this option is still provided allowing the model to have

opened or closed engine exhaust nozzles.

- Full engine intake ducting back to a representation of the engine

faces. The contours of the ducting are not truely accurate, but to

have some form of ducting with an engine face is better than a blank

wall or, worse yet, an empty hole.

- A complete compliment of weapons pylons allowing most any

air-to-air weapons load to be modeled. Unfortunately, though, no

actual weapons are provided in the kit -- nothing -- not even a couple

Sidewinder missiles. This requires you to steal weapons from some

other kit or purchase some of the Hasegawa weapons sets. And, a gripe

of mine with the Hasegawa weapons sets is that the Phoenix missiles

are in the "smart bombs" set while all the other air-to-air missiles

are in a set of their own. This requires you to buy two weapons sets

to model a Tomcat with all three missile types on it, as if the Tomcat

kit did not cost enough already. A couple Hasegawa special release "Bombcat"

kits do include air-to-ground weapons, but no air-to-air weapons are

found in any of the kits to date.

- A TARPS reconnaissance pod. This is a big plus that Hasegawa could

have easily ignored. A full conversion to the TARPS configuration also

includes a fairing over of the middle front Sparrow missile well. The

later Hasegawa releases include the part to do this on the C tree

(part C51). The kit instruction sheets make no mention of this part or

where it goes, but that is its purpose.

- Open access doors with a representation of the 20mm Vulcan cannon

in the left nose. The real point here was that Hasegawa needed to

provide the gun covers as separate pieces because they are different

from one F-14 version to the next. The actual representation of the

20mm Vulcan cannon is rather poor, being nothing more than raised

detail inside the gun bay with no extra pieces to provide a true

representation of the 20mm Vulcan cannon. Several after-market

companies provide replacements of the gun bay interior that greatly

improve the look (if opening gun bays is your "thing").

- Finally, they provide what can only be termed as "extra pieces".

This includes all sorts of antennas and airframe variations that

provide the modeler with the ability to build most any Tomcat in

existence. Like the TARPS pod, these are a big plus that Hasegawa

could have easily ignored.

While this all sounds wonderful, it is not without a cost. There are

an extraordinary number of pieces in the kit. The original F-14A kits

contain 268 gray plastic, 16 clear plastic, 6 etched metal, 8 white

metal wheel hubs, and 4 vinyl tires. Quite a number of these pieces

(about 30) are the "extra pieces" I mention above that are optional

variations on the airframe allowing the modeler to build any specific

aircraft block number and weapons loading. Later releases of the kit

have the number of parts climbing even higher as in most cases, Hasegawa

added new options without removing the old ones. The high end of the

part count is found in one of the recent release of the F-14D Tomcat (in

overall black from VX-9). Because this kit includes trees of iron bombs

and everything needed to make a "Bombcat", the gray plastic parts top

out at nearly 500 pieces!

Building

Hasegawa's 1/48 Scale Tomcat

|

I was so excited by what I saw in the original Tomcat kit I purchased

that I started building it immediately. Then, I found some things with

the engineering of the kit that really disappointed me. Not that the

issues were insurmountable, but I had some preconceived ideas from what

the F-4 and A-7 kits were like. When the F-14 kit actually did have what

I considered "real" issues, I got disgusted and boxed the whole kit up,

putting it away in the closet. Note that this occurred in the middle

1980's where my Advanced Modelers Syndrome (AMS) was at its worst. It

was easy to convince me back then that any kit was too much trouble. The

disappointment has lingered, though, and is the biggest reason it has

taken me until now to finally build the kit. I will relate the issues I

ran into as I walk through the construction sequence for the kit.

The troubles I ran into with the kit relate in many ways to the

complexities introduced by all the pieces. The main trouble spots are

only in a few specific places. In fairness to Hasegawa, I have to state

that later releases of these kits have had the moldings reworked to help

alleviate some of the issues that I outline here. Depending on which kit

is being built, it may or may not have the reworked moldings. The

original kits (stock#07018 and #07019) seem to be the most likely kits

to not be reworked. Every other release of the kit I have checked has

the reworked moldings.

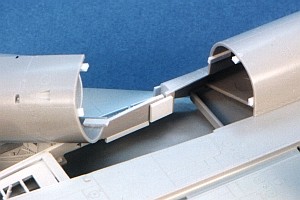

To

tell if a kit is a reworked one, check the engine intake pieces. If

there is a deep half-inch notch cut out of the inside corners of these

pieces, the kit is a reworked one.

To

tell if a kit is a reworked one, check the engine intake pieces. If

there is a deep half-inch notch cut out of the inside corners of these

pieces, the kit is a reworked one.

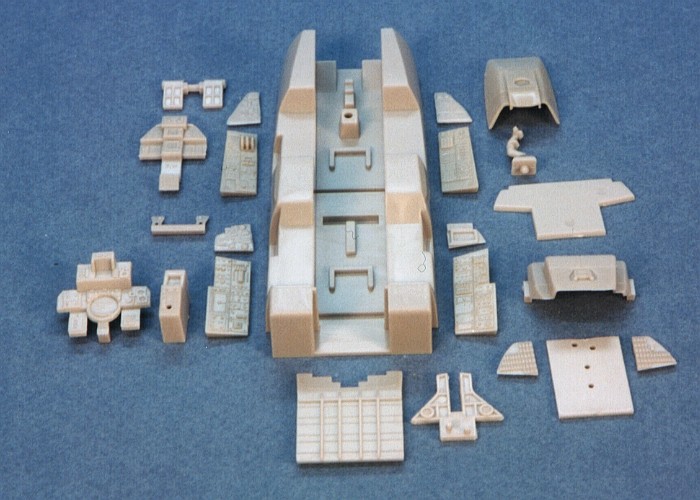

Like most kits, the construction starts in the cockpit. The basic kit

cockpit is "generic" so that it is reusable between all the various kit

releases. The main cockpit tub has no detailing. Into the tub are

installed all the specific detail pieces to provide the correct details

for the specific Tomcat version being built. I found that some of the

detail pieces did not fit as well as they could.

The front cockpit side consoles are a sixteenth of an inch too small

for the space on the cockpit tub that they fit into. The intention is

that they are attached flush to the rear wall, leaving a slot at their

front ends. Then, the left and right instrument sub-panels are supposed

to slip down into these slots. There are two issues here. The slots are

not wide enough to fit the sub-panels, and the sub-panels have raised

details all the way to their edges. Some of the details on the lower

section of the sub-panels get covered up when the they are slipped into

the slots in front of the side consoles. I thinned the sub-panels by

sanding down the backing so they would fit into the slots in front of

the side consoles and just accepted that some detailing was getting

covered up as I slid them into place.

The rear bulkheads of both cockpits cause trouble. In the front

cockpit, the piece does not want to slide down into place inside the

cockpit tub. Be aware, also, that the beveling on the edges dictates

that one side is the front and the other side is the back on this piece.

If you insert it backwards, a noticeable gap appears at the base of the

part. I filed down the sides of this piece to get it to slide into

place.

The issue with the rear cockpit bulkhead is one of not having enough

substance. The bulkhead builds up in three pieces that do not actually

touch when they are installed in the cockpit tub. This provides a place

to see into the fuselage behind the rear cockpit. I solved this by

adding some sheet styrene backings onto the pieces.

Lastly, when attaching the rear main instrument panel and instrument

hood into the cockpit, the front of the hood does not touch the top of

the front cockpit bulkhead, leaving a sixteenth of an inch gap. I added

some strip styrene to the top of the front cockpit bulkhead to fill this

void.

When all these fit issues were addressed, then it was time to address

the details that Hasegawa missed in the cockpits. I purchased the Eduard

photo-etchings set for the Hasegawa Tomcat (stock#48-155) to obtain lots

of details for the cockpits. Included in the Eduard set are really nice

representations of the cockpit canopy sills.

The next items on my list of cockpit improvements were the cockpit

side walls. Hasegawa molds nothing into the inside of the fuselage

halves to represent the assorted side wall details found in the Tomcat.

I was preparing to scratch build these items when Black Box released

their F-14A Tomcat cockpit for the Hasegawa kit. The Black Box set fixes

all the issues I outline above by replacing the entire cockpit. It also

provides side wall details for the cockpits. I simply discarded the

modified kit pieces and counted myself lucky for not investing too much

time on the cockpit issues.

For a full review of the Black Box F-14 Tomcat cockpit and its

integration into the Hasegawa Tomcat kit, see my other reviews: "Tomcat

Cockpit" and "Tomcat Cockpit Painting".

Following the completion of the cockpit, I assembled the forward

fuselage. In the original release kits, before the moldings were

reworked, the kit cockpit does not fit inside fuselage sides real well.

I needed to cut off the sides of the cockpit tub to gain clearance so

the fuselage would fit together. In the kits with reworked moldings, the

cockpit fits inside the fuselage without any issue. When I swapped to

using Black Box cockpit, I did not have to worry any more about it.

After dealing with the cockpit and the forward fuselage, the rear

fuselage is a snap. In one evening, I cut, cleaned, trimmed, and

assembled the entire rear fuselage (without the engine intakes). A

little care was needed to get the "beaver tail" to fit smoothly without

too much of a joint line, but this was workable without using filler.

The main wheel well interior pieces proved to be a bit of a puzzle.

After tinkering with them for almost an hour, I finally relised that

they are intentionally too tall. The top edge of them comes to a shape

beveled point. When joining the upper and lower fuselage halves, this

point is crushed over the raised details on the inside of the upper

fuselage. This is an odd choice by Hasegawa to get a tight fit, but it

works. I just needed to accept this was the way it was intended to work.

The worst fitting pieces in the entire kit were found when I started

work on the engine intakes. The cockpit issues are a "cake walk"

compared to the engine intakes.

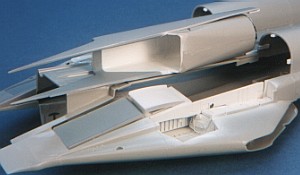

The

intake trunk pieces just do not match the contours of the fuselage. They

also lack positive alignment points to assist in getting them to fit the

lower fuselage. The fit issues are compounded if you do not get the main

wheel well pieces to sit just right. My recommendation is to use as

little glue as possible to build and install the main wheel wells. As

none of them are load-bearing in the kit, this is fine. That way, you

can adjust the placement of the wheel well pieces to accomodate the

engine intake trunking.

The

intake trunk pieces just do not match the contours of the fuselage. They

also lack positive alignment points to assist in getting them to fit the

lower fuselage. The fit issues are compounded if you do not get the main

wheel well pieces to sit just right. My recommendation is to use as

little glue as possible to build and install the main wheel wells. As

none of them are load-bearing in the kit, this is fine. That way, you

can adjust the placement of the wheel well pieces to accomodate the

engine intake trunking.

I carefully fit and adjusted the fit of the intake trunk pieces to

make them line up on the fuselage. Then, I added some strip styrene

locators to assist me with the alignment at the rear end of the pieces.

Finally, I adjusted the fit and location of the main wheel well backing

pieces (kit parts C15 and C16) so that they would not interfere with the

intakes. The engine intake issues are sort of addressed in the kit

releases with reworked moldings. The moldings changed, but most of the

fit problems are still there.

In addition to the poor fit of the intake trunks to the lower

fuselage, the fit of the intake ducting inside the trunks is pretty bad.

I needed to use more than a little filler to blend the interior of the

intake trunks into the intake ducting pieces. The entire area should be

smooth, but the kit has loads of knockout pin locations and rough

plastic. While a lip is molded into the trunk for the ducting to fit

into, the ducting does not reach it.

My final intakes, after sanding the filler, were not really correct

(still), but they were better looking than the way the stock kit

provided them. I figured that the view afforded in the front of the

intakes would be limited enough to hide any remaining shape issues. I

was proved right after the intake trunks were attached.

Before

attaching the intake trunks to the lower fuselage, I painted their

insides gloss white. After this dried, I masked and painted the

camouflage color of the outer portion of the inner intake. I had no

specific pictures of the aircraft I was building that showed the intake

interiors. Hence, I masked the most typical paint line I have seen

inside Tomcat intakes. Check your references when doing this masking as

the line can change from aircraft to aircraft.

Before

attaching the intake trunks to the lower fuselage, I painted their

insides gloss white. After this dried, I masked and painted the

camouflage color of the outer portion of the inner intake. I had no

specific pictures of the aircraft I was building that showed the intake

interiors. Hence, I masked the most typical paint line I have seen

inside Tomcat intakes. Check your references when doing this masking as

the line can change from aircraft to aircraft.

During the process to attach the intake trunks to the lower fuselage,

you also attach the intake variable geometry ramps (kit parts F10, F11,

F12, and F13). If attached the way they are provided in the kit, these

ramps are positioned like they would be in supersonic flight. As this

configuration is never seen on the ground when the aircraft is parked, I

modified the installation of the ramps to correct their placement.

I deleted the actuating rods for the forward ramps (kit pieces H6)

and removed all of the raised details on the backs of the forward ramps.

This allows the forward ramps to be attached in a highest, flush

position. Then, I cut all but a sixteenth of an inch of the oleo

extension off of the rear ramp actuators (kit pieces H7). This

effectively halved the length of these actuators. This allows the rear

ramps to be attached in corresponding higher positions to match the new

positions of the forward ramps. This revised ramp configuration better

captures the look of the intakes when the aircraft is parked on the

flight line.

After attaching the intake trunks to the lower fuselage, I found that

another place to work out was the area just under the upper lip of the

intake. The intake trunks have pointed forward extensions that should

transition smoothly into the lower edge of the intake lip. This was not

happening. I used still more filler to shape and blend the pointed

forward tips of the intake trunk into the lower side of the intake lip.

If I ever build another of these Tomcat kits, I will strongly

consider using intake covers on the model to hide all these intake

issues.

With

the intakes completed and fully attached, I attached the forward

fuselage to the rear fuselage. The joint between the forward and rear

fuselage did not align well. The cross-section shapes of the two

fuselage sections are not the same. I used a heavy styrene strip to

widen the upper portion of the rear fuselage opening. This helped the

forward and rear fuselage shapes to match each other better.

With

the intakes completed and fully attached, I attached the forward

fuselage to the rear fuselage. The joint between the forward and rear

fuselage did not align well. The cross-section shapes of the two

fuselage sections are not the same. I used a heavy styrene strip to

widen the upper portion of the rear fuselage opening. This helped the

forward and rear fuselage shapes to match each other better.

By this time, I was getting used to applying liberal amounts of

filler to this kit. I applied some more filler and sanded it out to

smooth the fuselage joint. I also needed to reinforce the inner

structure of the fuselage joint. I had placed a lot of lead shot in the

nose area of the model to guarantee the it would sit correctly on its

landing gear. This made me fear that the nose section would get broken

off if I was not careful. The reinforcing gave me some peace of mind.

At this point I was holding a nearly completed fuselage that was

starting to really look like a Tomcat. I thought the big issues were

finally past, but I had one more to go -- the wings. The wing problems

relate mostly to the wing flaps and the pieces that go into the wing

flap construction to support the lowered wing flaps.

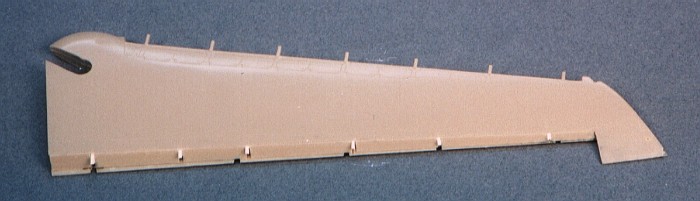

To build the model with the flaps retracted (up), things fit pretty

much as advertised. All that is needed is to thin the trailing edge of

the upper wing piece, and the flap slides in with very little extra

effort. Not readily apparent in the instructions is that the "eyelid"

doors (kit parts C1 and C8) are discarded when the flaps are up.

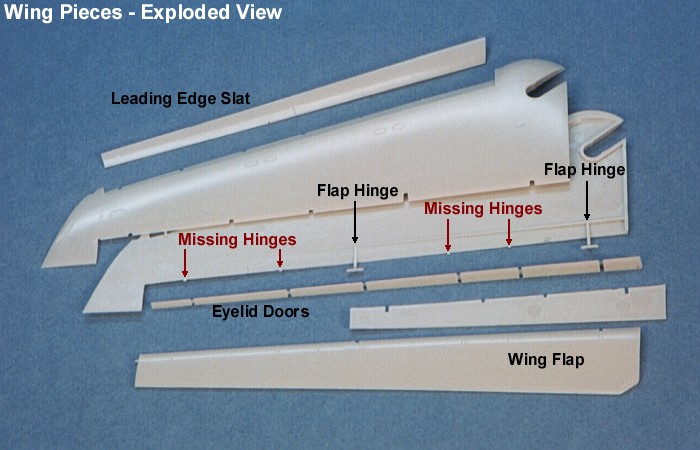

Building the model with the flaps positioned down is where the fun

starts. I found the flap pieces do not fit the wings as well as they

could. Troubles start with the "eyelid" doors. First off, the

instruction sheet has these parts labeled backwards. Put C1 where the

instructions tell you to put C8, and vice versa. Even when these pieces

are on the correct side, they are still too thick to fit into the thin

space between the upper and lower wing pieces. I ended up separating

these doors into three pieces each, cutting and filing away some of

their backing portions, to get them to go into place.

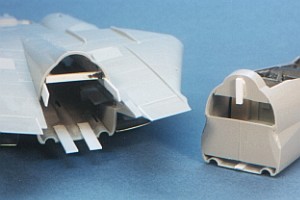

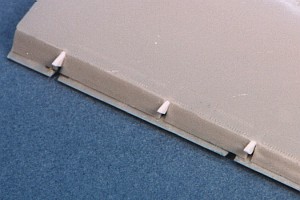

Then,

Hasegawa only provides two hinge/actuator points to connect the flap

to the wing. There should be six. There are locator points on the

flaps and wings for all six hinge/actuator points, but these are

some parts that Hasegawa apparently neglected to include in the kit.

I nipped off the two provided hinge points, as they are a little too

long and incorrectly shaped. Then, I built up all six

hinge/actuators using strip styrene. Then,

Hasegawa only provides two hinge/actuator points to connect the flap

to the wing. There should be six. There are locator points on the

flaps and wings for all six hinge/actuator points, but these are

some parts that Hasegawa apparently neglected to include in the kit.

I nipped off the two provided hinge points, as they are a little too

long and incorrectly shaped. Then, I built up all six

hinge/actuators using strip styrene.

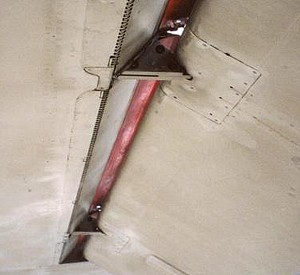

A friend I met on the Internet (Danny Deters) sent me some great

detail pictures of the lowered flaps on a Tomcat. Studying these

detail pictures helped considerably with the process to build the

hinge/actuators. With Danny's permission, I have included some of

his pictures below: |

|

Inboard, Underside |

Outboard,

Underside |

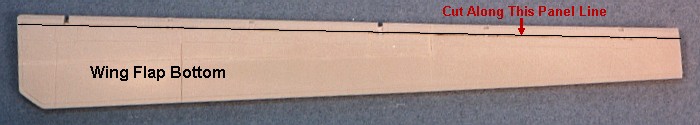

I was still unhappy with the look of the flaps. After some extended

investigation, I found out why. Hasegawa molds the wing flaps,

themselves, incorrectly. They are too big! Hasegawa molded their pieces

on the assumption that the flaps are a fowler style flap that slides

back as it comes down. The truth is that the flaps are a slotted type

that merely pivots down with the "eyelid" doors retracting to reveal a

slot between the wing and the flap. No sliding back occurs. The bottom

line is that the Hasegawa flaps are too long in their cord by about an

eighth of an inch, the width of the "eyelid" doors.

After some investigation on how best to fix the problem, I initially

came to the conclusion that fixing the kit pieces would be harder than

just creating new flaps from scratch. Then I looked more into the

scratch building effort and decided I really was not up for that,

either. After further scrutiny of the kit pieces, I found that simply

cutting off the leading edges of the pieces and filing them back to air

foil shapes would work. So, that is what I did.

I cut the kit wing flaps following the scribe line that defines the

"eyelid" doors (when the flap is retracted). Then I filed the leading

edges of the parts to re-create the proper airfoil shape. I fixed the

scribing that was lost during this process. I machined in the attachment

points for the hinges that attach the flap to the wing. Lastly, I added

the bumps on the upper flap surfaces that attach the actuators to the

flap.

|

|

Inboard, Topside

|

Outboard, Topside

|

|

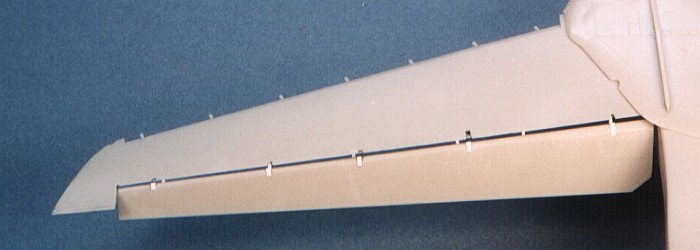

The last error by Hasegawa on the wing flaps involves the location of

the flap actuators and the hinges points. Each actuator rod should be

centered over a hinge point. Only two of the six actuator points align

with the hinges. The others are skewed left or right by up to a quarter

of an inch. I chose to not try to fix this alignment issue because it

would involve rebuilding the (at the time I learned this information)

already constructed "eyelid" doors and re-scribing the piano hinges for

the "eyelid" doors. Perhaps on a future build of the kit I will tackle

fixing the actuator locations.

The Hasegawa wing flaps always looked somehow wrong to me. After

discovering and fixing most all of these wing flap problems, I was much

happier with the look of the dropped flaps. I considered raising the

wing spoilers while I was working on the wing, but decided against it. I

had my hands full with just fixing the incorrect flaps. Like the flap

actuators, perhaps on a future build of the kit I will tackle raising

the spoilers.

I left the wings loose (unglued) in the fuselages of my completed

models. The fit is tight enough on the wings to hold them in place

without glue. This way I can remove the wings for transporting the

models.

By now I was getting really tired of the model (again), so it was

fortunate that I had finally reached the end of the big problems. The

engine exhausts were no real trouble. Note that the engine exhaust

nozzle adapters have a definite left and right side. I test fitted these

between the left and right sides until I got it right, then added glue.

Note that on F-14A+/B and D Tomcats (with the GE engines) the engine

exhaust nozzle adapters should have all their scribing filled and sanded

smooth. This area on the real aircraft is some high-tech fiber surface

with no panel lines running through it. All it has is a series of

attachment screws running along the edges.

A very typical parked stance of the F-14A engine exhausts has one

side wide open and the other side fully closed. What happens is this.

While taxiing, both engines are fully open. When the first engine is

shut down, the aircraft is still powered by the second engine. The

flight control computer cycles the shut down engine exhaust fully closed

in a attempt to increase thrust. When the second engine is shut down, no

power is available any more and the second engine remains fully open.

The operating mechanism on the F-14A engine exhausts is not effected by

gravity, so the exhausts remain in whatever position they are in at shut

down.

If both engines are fully open (on a parked F-14A), it means they

were shut down pretty much at the same time. It is rare to find both

engines fully closed on the ground.

On the F-14A+/B and D Tomcat, the typical parked stance of the engine

exhausts is to have both exhausts wide open. The same operational

behavior occurs to the engine exhausts that occurs on the F-14A. The

difference is that the operating mechanism of the engine exhausts on the

F-14A+/B and D is very much effected by gravity. Within minutes after

shut down, the engine exhausts are pulled open by gravity.

The landing gear constructed and plugged into the wheel wells with no

issue. I added wiring and plumbing to the landing gear legs using fine

wire. The rubber/vinyl tires provided by Hasegawa are both good and bad.

With time, they squash on the model while it sits on your display

shelves so that they create convincing looking weighted tires. Then,

with more time, they start to decompose and leave oily spots on your

display shelves. Finally, they start to crack and fall apart. I learned

this from using the rubber/vinyl tires in the high-grade F-4 Phantom

kits. Hence, I replaced the F-14 wheels and tires with resin items

available from Cutting Edge.

I added the various antennae and little details at the end of the

project, just before declaring myself done. Even these were not without

some headaches.

The arresting hook is about a quarter of an inch too long. This

causes it to hang out beyond the beaver tail. It should be even with the

end of the beaver tail. I cut off the end of the hook, removed about a

quarter of an inch from the end of the center rod portion, and

re-attached the hook tip.

The COM antennae along the spine do not fit the locator holes on the

fuselage. I filled the kit provided holes and redrilled some of my own.

While I was at it, I scratch built new antennae from .020 inch sheet

styrene (cut to size to match the kit pieces).

The nose tip pitot part does not really fit the hole on the tip of

the nose cone. Also, it is too long. I took the same approach here as I

did on the spine COM antennae and scratch built a new pitot with brass

wire and the "pitot-less" nose tip in the kit. Then, I filled the hole

on the nose tip and redrilled a new hole to match the thickness of the

brass wire.

The boarding ladder uses etched metal pieces to construct its

vertical sides. These are too thin looking when built, so I laminated

.015 inch sheet styrene onto them and trimmed them to size. Using

appropriate sized drill bits, I drilled the litening holes into the

sides where they existed in the etched piece. This thicker construction

looked more appropriate to what I saw in pictures of a real Tomcat

boarding ladder.

The mounting holes for the horizontal tails were too large. The tails

just hung in them. After contemplating several not-too-easy options, I

decided to take a "cheap" approach that worked. I applied a bead of

super glue inside the holes and let it dry. This reduced the hole size

just enough so that the tails fit snuggly. I needed no glue to secure

them. This makes them more survivable over the upcoming years on my

display shelves. Since they are not glued, they will just move if (when)

I bump them instead of breaking.

The instruction sheet has parts #L10 and #L11 (the wingtip navigation

lights) backwards. I painted mine on the sprue using the instruction

sheet to tell me which part would be which color (clear red or clear

green). When I went to attach them to the wingtips, they did not work on

the sides that I painted them for. The correct placement, for the record

-- #L10 is the left (red), #L11 is the right (green). I stripped the

clear paint off using an old bottle of Polly-S paint and decal remover.

Then painted them again in the correct colors before attaching them to

the wings.

In reality, none of the trouble areas I ran into are impossible to

fix. That I fixed them proves this point. They only take a some extra

time and a little tinkering with the kit's engineering. For the kit's

cost, though, these areas should work right out of the box. Hence, back

in the 1980s when I first started the kit, my AMS took over and I just

socked the kit away.

It is a shame that I had to wait so long to get over the disappointed

feelings so that I could finally get up the courage to complete this

monster. Compared to the state-of-the-art technology found in most of

the recent Hasegawa and Tamiya releases, this is not an easy kit to

build. But, it is not all that bad. It is better than some old Airfix

kits I have worked on. The completed kit is quite pleasing to look at

and worth the effort to complete.

I got so into these Tomcat kits when I was finally building them

(after fifteen years of feeling disappointed with the kit) that I built

three kits all at the same time. Look for the three different Tomcats to

get posted separately in future postings.

Go to Part One - Building the Black Box Cockpit

Go

to Part Two - Painting the Cockpit for Effect

Go to Part Four - Painting an NSAWC Tomcat

Model, Description and Images Copyright ©

2001 by David Aungst

Page Created 03 August, 2001

Home

| What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search